Motors with different characters. Motors with different characters ICE ZMZ 406 technical characteristics

Currently, the ZMZ 406 engine is the most successful development, and is installed on GAZelle, GAZ 3110, Volga cars. A carburetor or an injector is installed on its various modifications. Its predecessor, the 402 engine, was less reliable. Let's consider the 406 carburetor engine, which has become widespread in our automotive industry, as well as the repair of the ZMZ 406 engine.

General technical specifications

As mentioned above, on the 406 engine the factory installs a perfect carburetor or injector. It is four-cylinder, has an electronic ignition system, as well as control electronics, which allows you to adjust the carburetor or injector to the operating conditions of the car.

These engines also have a special oil cooler installed, which is designed to cool the lubricant, but experts and car enthusiasts agree that this is an extra unit, since when operating such power units, they practically do not overheat.

Exhaust and fuel system, the muffler, depending on the modification, meets Euro 2 standards, as well as other environmental requirements. The cylinders are arranged in-line. The power of this engine depends not only on its modification, but also on the load that goes to the power unit and is regulated electronically.

You need to remember that the operating principle of this power unit, which was developed and began to be produced in 1996, is similar to the Tsi engine.

406 engine breakdowns and repairs

In principle, it is better to repair the 406 ZMZ engine at a specialized service station, where it will be done full diagnostics. But due to the fact that this power unit almost does not break down if it is operated correctly, below will be some cases of malfunctions that you can fix with your own hands.

You also need to pay attention to the exhaust system. Sometimes valves or other elements responsible for removing exhaust elements (gases) from the burnt fuel mixture wear out. Their violation can lead to coking of the valves and damage to the catalyst.

It is important to remember that in the event of failure on-board computer, or any electronic system, it is better to immediately contact specialists rather than disconnect the electronics. Disabling it is fraught with high fuel consumption and engine malfunctions.

Repair of the 406 ZMZ engine must be carried out at specialized service stations. Minor breakdowns can be fixed at home, since the design of this engine is simple, but it is still highly reliable and does not break if used correctly.

The 406 injector engine for the Volga car is presented in the form of an in-line four-cylinder engine with 16 valves. Injection is regulated by an electronic control system. Power units of this type are installed on GAZ 3302 and 3110 vehicles.

Later engines internal combustion ZMZ 4062 models are equipped with a distributed injection system.

Design features of the ZMZ 406 injector engine

The 406 injector engine has certain design features:

- The camshafts are located at the top of the cylinder head.

- Each cylinder contains four valves.

- Increased compression ratio of 9.3.

- Replacing the carburetor power system with a different, more advanced design.

The compression ratio is increased both through the use of spark plugs located in the central part of the combustion chamber, and through the use of a fundamentally different type of injection system. Fuel combustion is most complete. The usual carburetor power system has also been changed here.

Gazelle engines have 406 injectors new version The cylinder blocks are made of durable cast iron instead of the usual aluminum. The design of the cylinder head (cylinder head) does not provide for insertion liners; it is characterized by higher rigidity and clearance stability.

Engineers have provided for a noticeable reduction in the piston stroke, now it is 86 mm. The weight parameter of the pistons and pins has been reduced due to the use of more technologically advanced modern materials. Modern high-quality materials are also used in the manufacture of the crankshaft, connecting rods and other parts.

To drive the camshafts, an original chain design is used, equipped with hydraulic tensioning devices that operate automatically. New motor does not require constant adjustment of the required clearances.

The forced ZMZ 406 injector uses a higher quality lubricant, oil filter improved design and additional cleaning elements.

With the help of a new power unit control system, the ignition system, fuel dosing, and ignition angle adjustment have been improved.

Advantages of the injection type design

Thanks to improvements in engine design, there have been significant changes in the characteristics of the updated power unit:

- Increased power.

- Increased torque.

- Reduced fuel consumption.

- Improvement of exhaust gas toxicity indicators.

Technical characteristics of the injection internal combustion engine (ICE):

- The cylinder volume is 2.3 liters.

- The direction of rotation of the crankshaft is to the right.

- The maximum power that the ZMZ 406 injector engine is capable of developing is 110 horsepower.

- The type of fuel consumed is gasoline 92.

- Fuel is injected directly into the pipe.

- The lubrication system operates on the principle of forced, uniform spraying of oil under pressure onto the rubbing surfaces of working parts.

The engine is cooled by forced cooling using antifreeze or antifreeze.

Which engine to choose - carburetor or injection

Many car owners are increasingly attracted to the injection version of the power unit instead of the usual carburetor model. The Gazelle 406 injection engine is increasingly being installed on heavy vehicles.

The Zavolzhsky Automobile Plant equips cars such as the Volga, UAZ, and Gazelle with more powerful injection engines. These brands of cars require increased power; a gasoline power unit of this type is capable of developing as much horsepower as is required for their stable operation.

Disadvantages of a carburetor engine

Comparing the 406 carburetor engine with its injection analogue, one can be convinced of the noticeable superiority of the second in such indicators as power and performance. The main reason for the significant differences is the original power system. In a carburetor engine, fuel is supplied to the cylinder as the speed increases, resulting in lower power and acceleration.

A carburetor engine is less economical due to the inability to accurately regulate the gasoline supply. It is almost impossible to more accurately regulate the amount of fuel, which affects power and fuel consumption.

Despite the disadvantages described, many car owners love their carburetor engines. A car equipped with such a power unit is as reliable and durable as a proven horse can withstand the load.

Advantages and disadvantages of injection power units

The ZMZ 406 injector engine is noticeably superior to its carburetor counterpart in terms of reliability, efficiency and power. One of the main positive qualities of injectors is the absence of the need to make mandatory engine adjustments. The power supply system here is not subject to clogging, there are no jets, and the exact amount of fuel flows directly into the cylinders.

The main disadvantage of injection-type engines is the inability to independently restore the operating mode. Judging by numerous reviews, if the engine breaks down along the way, the driver will not be able to repair it with his own hands.

This is due to the fact that the functioning of all systems of injection-type power units is carried out under full electronic control. The failure of at least one electronic sensor will lead to changes in the performance characteristics of the entire internal combustion engine.

To avoid unstable operation or stopping of the injection engine, it is necessary to install only imported elements and carry out regular Maintenance and thorough vehicle diagnostics.

Description of problems encountered

ZMZ 406 power units are very amenable to repair measures; many components and parts are successfully restored. The most frequently performed operations are:

- crankshaft grinding;

- boring the cylinder block.

Due to the fact that the cylinder head is made of cast iron, this part does not suffer from low-quality coolants. The basic need for high quality lies only in motor oil. The internal section of the 406 injection power unit is very sensitive to the incorrect selection of the brand of lubricant, and also requires regular complete replacement machine oil.

Numerous reviews from car owners indicate increased consumption of lubricant on GAZ 406 injection-type engines.

Conclusion

The main and main advantages of the 406 ZMZ power unit include high efficiency and reliability. Due to the fact that any component and internal part can be replaced with imported samples, it is possible to significantly extend the service life vehicle and increase its efficiency.

avtodvigateli.com

Engine ZMZ 406 carburetor: characteristics

The ZMZ 406 engine and carburetor replaced the 402 model and was initially intended during the development process for installation on the new family of executive cars GAZ-3105. However, due to the closure of the project for a new luxury car, the target group of consumers was changed and the plant began supplying the engine to the produced passenger cars of the GAZ family.

As automotive production developed, the engine began to be installed on light-duty trucks of the Gazelle family and four-wheel drive vehicles produced by the Ulyanovsk Automobile Plant.

The engine was designed from scratch. The basic prototype was a Swedish engine, the H series, which was installed on SAAB-9000 cars. The carburetor version has factory indices ZMZ −4061.10 and ZMZ-4063.10

The resulting in-line gasoline four borrowed double camshafts and an electronic ignition distribution system as a design solution. For 1993, this was a revolutionary solution for Russian automobile industry. ZMZ was the first to use the DOHC design for supplies to Russian automobile plants. Although by 1997, when deliveries to car factories began, the 406 engine already had an outdated design, compared with the same Saab.

Copy technological solutions did not allow the actual parameters of the prototype to be taken from the engine. And instead of 150 hp and 210 Nm of thrust like the prototype, the brainchild of the Zavolzhsky Motor Plant with a carburetor produced 100 hp. and 177 Nm with the same volume of 2.3 liters. The technical characteristics of the original were achieved only after additional modification of the engine with the installation of a fuel injection system.

ICE ZMZ-406 carburetor was installed on the light version trucks and vans produced by OJSC GAZ until 2006. GAZ 3302, on which a 406 carburetor was installed, was perhaps the most common model due to its relative cheapness.

Also carburetor engine of this family was installed on passenger cars of the Volga family. This engine provided the minimum cost option for the car.

Electronic ignition system

The completely Russian development of electronic filling is currently practically unified and different versions of this can be installed electronic unit. It should be noted that the software must be installed taking into account specifications specific engine.

The Gazelle with the 4061.10 engine was designed to operate on 76 gasoline and the 406 engine had a reduced compression ratio; accordingly, firmware was required to ensure stable operation of the engine on this fuel.

Electronic ignition units for power units are not interchangeable with other series of engines. Those. The block for 405 is not suitable for installation on a gazelle equipped with a 406 engine.

Fuel system

The engine had two versions, which made it possible to use 76 and 92 gasoline. Due to the transition to international environmental requirements, gasoline with octane number 76 is no longer produced. For normal operation engine with index 4061.10 needs to be modified.

Fuel is supplied by a diaphragm fuel pump driven by the intake camshaft.

Oil system

For engines of the 406 family, it is recommended to use mineral all-season oil 10(15)w40 or API grade no worse than SG. Perhaps this recommendation is due to the fact that the engine plant produces oils under its own brand.

In fact, it is worth focusing on the API rating and choosing the oil viscosity in accordance with the climatic operating conditions of the engine. The description of the API oil standard indirectly dates the development of this engine to 1989-1993.

You should pay attention to the quality of the lubricating fluid itself, since stable characteristics ensure better and longer-lasting operation of hydraulic compensators.

The capacity of the power unit oil system differs depending on the make of the car. Thus, for cars of the UAZ family, the design of the engine sump was changed.

Standard diseases 406

Overheat

The engine is very sensitive to overheating. During a long trip on a boiling engine, the cylinder head drives. The problem with overheating is associated with poor quality of the pump and the condition of the cooling radiator. The materials used in the water pump have certain design tolerances that cannot guarantee the volumetric flow rate and pressure in the cooling system.

The design of the impeller allows for the possibility of cavitation destruction of the blades, which reduces efficiency. In addition, the question remains regarding the corrosion resistance of the pump shafts.

The inefficiency of the pump affects the condition of the internal radiator channels. When the surface is externally clean, the channels narrow and heat transfer decreases.

Another reason for overheating is a poor-quality thermostat. Incorrect trigger setting or jamming of structural elements during operation.

The design features of the coolant channels and the lower location of the radiator can provoke the creation of blocking air jams, preventing the circulation of fluid.

Oil consumption

During operation it is fixed increased consumption oil volume up to 1.5 liters per 1000 km. Oil consumption can occur without visible leaks. The problem is caused by poor-quality seals, clogging of the labyrinth seals under the cylinder head cover, and insufficient durability of the sealing rings. Associated with poor quality assembly and can be modified independently during operation.

Oil consumption is affected by the condition of the valve stem seals. Requires monitoring and replacement as necessary.

Oil loss through sweating of the block is less common and cannot be corrected on its own, since the problem is related to the porosity of the cast iron used to cast the block.

Traction characteristics

Poor idle performance and sudden loss of power while driving are caused by a failed ignition coil.

Ignition system

Malfunction of the engine ignition system “triple” is caused by problems with the ECM software, spark plugs, and ignition coil. A simultaneous failure of several system elements may be detected.

Engine knock

When using low-quality oil or insignificant mileage before changing the oil, the operation of the hydraulic compensators is disrupted. The knocking sound is clearly audible even after the engine reaches normal temperature conditions.

Basically, all malfunctions that appear during operation are due to poor-quality components, as well as the low level of assembly culture of units at the plant, which was typical at the beginning of production of the engine of this family.

Tuning 406

When tuning the 406 engine, the carburetor is replaced from the standard one with a Sollers one, although technical specialists from the manufacturer indicate that such a replacement is not advisable, since the standard K-151D carburetor has coordinated calibrations specifically for the 406 series engine.

A deeper modification of the 4063.10 engine consists of changing the fuel supply system from carburetor to injection. Such an alteration is possible, but is associated with certain difficulties.

To increase air flow to the engine, replace the standard air filter housing and install a straight air filter. A deeper modernization of the air supply system involves moving the suction pipe outside the engine compartment to reduce the temperature of the incoming air.

To improve heat transfer and reduce the temperature peak, oil radiators or cooling system radiators with an increased airflow area are used.

To increase power, it is possible to install turbocharging, select camshafts, replace valves and parts of the CPG. But these modifications for light-duty trucks are not justified from an economic point of view.

avtodvigateli.com

Engine 406 - description

The ZMZ 406 internal combustion engine is produced at the Zavolzhsky Motor Plant, which is the main supplier of components for the Gorky Automobile Plant (GAZ). The ZMZ enterprise is also engaged in the manufacture of the 405 model engine. These two engines have become the real pride of the Zavolzhsky plant. In their design and technical data, they differ somewhat from each other. But still, almost every car enthusiast knows their operating principle.

What cars is this engine model installed on?

Most often, the engine of the 406th model was installed on the Volga model 31105, as well as on the well-known Gazelkas. Moreover, since 2003, the Gorky plant has completely updated the technical characteristics of all models of these trucks. From that moment on, the 402 engines completely went out of production and were no longer installed on any modern truck. They were replaced by two new units - ZMZ 406 and ZMZ 405.

406 engine - characteristics and description

This engine model was released in mass production back in 1997. But, despite this, GAZ 3302 GAZelle cars until 2003 were equipped with only 402 engines. The new product ran on 92 gasoline. The main detail that distinguishes it from other models is fuel injection, which was first developed by engineers at the Zavolzhsky plant. Over its long period of existence, the engine of the 406th model has gained enormous popularity and has become one of the most widespread in Russia. It gained such popularity due to its reliable design and economical fuel consumption.

History of creation

When operating the 405 engine, significant shortcomings were noticeable: on hot summer days, the Volga and Gazelle simply overheated and boiled (probably everyone saw such a phenomenon when there was an empty plastic bottle under the hood of a Gazelle). This indicated flaws in the cooling system. Many drivers installed a three-section radiator in place of the serial two-section one, but still the engine sometimes made itself felt. The engineers of the Zavolzhsky Motor Plant understood that they could not go on like this, and began to develop a new injection engine, the ZMZ 406. It was not developed from scratch - its entire design was reminiscent of the 405 engine. But now all the shortcomings have been taken into account and are not included in the new 406 engine (injector).

What are the changes in these two models?

So, the very first difference of the 406 engine is the presence of an injector. The carburetor had its drawbacks and was unreliable. The power of the new product was 145 horsepower. Working volume - 2.4 liters. The unit has significantly lower fuel consumption, and winter period very easy to start. This engine is also distinguished by its high reliability, which cannot be said about the 405 model. Actually, these are the main advantages because of which many motorists choose the 406 model engine.

Major renovation

Approximately every 200-300 thousand kilometers this engine requires major repairs. This procedure costs much more than repairing ZMZ 402 and 405 (approximately 30-40 thousand rubles). And all because of the complex design of the unit. Therefore, when operating a GAZelle, you should remember that in about 3-4 years it will require significant repair costs.

fb.ru

ZMZ 406 carburetor - overview of the most common problems

The ZMZ 406 carburetor began production in 1996 and since then has managed to establish itself with good reliability and simplicity. Its reliability is significantly superior to the outdated ZMZ 402 gas engine, which is difficult to start after a breakdown.

Engine ZMZ 406 series

General characteristics

The ZMZ 406 engine is a carburetor, four-cylinder, and also in-line with a microprocessor ignition system. ZMZ 406 equipped with a carburetor has a power of 110 hp. s., and with an injector - 145 liters. With. In addition, injection modifications have different environmental standards. For example, ZMZ 4062.10 is class 0, and ZMZ 40621.10 is Euro class 2. An oil cooler is considered an extra part in ZMZ 406, because the 6th engine does not heat up. In the ZMZ 405, the oil cooler does not perform its functions, and the engine overheats in hot weather and naturally does not start.

With a carburetor, the ZMZ 406 does not require so much expense when equipped with gas equipment. Moreover, this advantage applies to propane and methane, but with an increase in the class of environmental standards, the cost of gas equipment will also increase.

The cost of gasoline for a ZMZ 406 carburetor directly depends on the conditions and driving style, as well as the time of year. The ignition system of the ZMZ 406 carburetor is considered quite reliable. The engine will be able to reach speeds of up to 500 thousand kilometers using high-quality oil and gasoline, as well as careful handling of the pedal.

Gazelle

Model ZMZ 40524.10 is a gazelle carburetor known to everyone. The car brand “Gazelle” is one of the most popular and affordable trucks in Russia, which were originally intended for transporting not very large loads. Due to the huge number of such machines, we will consider several nuances of different gazelle systems. For example, a microprocessor ignition system, which is installed on the 406 model.

If the driver claims that his car makes some popping noises, jerking noises and loses its power. In this case, the power system, engine and ignition system should be checked. Gas analyzer not during operation of the 1st and 2nd chambers, cutoff, enrichment and during idle move We checked the carburetor and found no violations. Next they check the engine. When checking the compression, no problems were identified, but the next time deviations from the norm were detected. It was concluded that the jerks and pops that the driver did not like were due to the jumping of the teeth of the upper chain.

Sale of new SUVs

Credit 9.9%, installments 0%, discounts, gifts!

Carburetor ZMZ 406 series

What to do if a gazelle loses power?

From the very beginning, you need to check how the diagnostic circuit and the on-board diagnostic system function, because when the travel image mode is activated, a malfunction code of 12 should be obtained. To read the code, the 10th and 12th contacts of the diagnostic block must be closed. Using a diagnostic toaster, engine sensor parameters are measured and then compared with typical values for average engines. The most common reason for a decrease in car power is contamination of the tube that connects the intake manifold and the pressure sensor.

Gazelle ignition system

Microprocessor ignition system ignites working fluid in the cylinders and sets the required ignition timing of the vehicle for all engine modes. The ignition system performs the function of regulating the operation of the forced idle economizer. Thanks to the ignition system, engine operation becomes more economical, compliance with all exhaust gas toxicity standards is monitored, detonation is eliminated and the vehicle's power is increased. If we compare the classic system with this one, then this ignition system is much more reliable and durable. Here only the spark plugs can wear out.

How does diagnostic mode work?

When the ignition system is turned on, the indicator light begins to light. At that very moment, the diagnostic system begins to work. If the system is working properly, the light stops lighting, but otherwise it continues to light. That is, an extinguished warning light indicates that the ignition system is absolutely working.

Carburetor ZMZ 406 series

Why does the 406 engine sometimes not start during a freeze?

The most common reasons why the 406 engine does not start:

- Poor quality oil;

- The battery is not powerful enough, which prevents the engine from starting;

- Faulty starter;

- Misregulated ignition system;

- Poor quality gasoline;

- Failure to supply gasoline.

How to adjust the carburetor?

- Disconnect the drive cord air damper;

- Remove the air filter and carburetor cap;

- Check the level of the float chamber, it should be below 3 centimeters from the edges;

- Remove the plug from the float rod;

- Make sure the valve seal ring is tight;

- Install the carburetor top;

- Install the choke cable and air filter;

- Screw in the idle speed adjustment screw all the way, unscrewing it five turns. Carry out the same actions with the quality screw, but unscrew it three turns;

- Start the power unit;

- Let it heat up to 90⁰;

- By rotating the operational adjustment screw, select the crankshaft speed, about 700 rpm;

- Press the accelerator pedal and release quickly. If the engine stalls, increase the frequency;

- Stop by a car dealership and adjust the CO and CH of the engine.

The ZMZ 406 engine was being developed to replace the 402 engine simultaneously with the design of the GAZ-3105 car for the government. However, these new Volgas were equipped with them only for the last batch, which had to be urgently sold due to the removal of the cars from production.

The basis was taken from the ZMZ 402 (equipment) and the H series engine from the manufacturer SAAB (design solutions). As a result, with the same volume of 2.3 liters, the power drive provided 177 Nm of torque instead of the prototype’s 210 Nm and 100 hp. With. power instead of the expected 150 hp, like the Swedish internal combustion engine. The injection system, which later replaced the carburetor, was able to improve the situation slightly - 201 Nm and 145 hp. s., respectively.

Technical characteristics of ZMZ 406 2.3 l/100 l. With.

For the first time, several advanced technical solutions for that time were used in the engine of the manufacturer ZMZ:

- two intake and two exhaust valves per cylinder;

- electronic ignition and injection systems;

- diagram of the DOCH gas distribution mechanism with two overhead camshafts;

- hydraulic pushers instead of adjusting the thermal clearance of valves with gaskets.

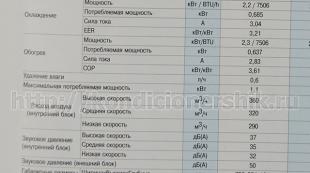

After the changes made, the technical characteristics of ZMZ 406 correspond to the values given in the table:

| Manufacturer | ZMZ |

| Engine brand | 406 |

| Years of production | 1997 – 2008 |

| Volume | 2286 cm 3 (2.3 l) |

| Power | 73.55 kW (100 hp) |

| Torque moment | 177/201 Nm (at 4200 rpm) |

| Weight | 192 kg |

| Compression ratio | 9,3 |

| Nutrition | injector/carburetor |

| Motor type | in-line petrol |

| Ignition | switchboard |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 2 pcs. DOCH scheme |

| Cylinder block material | cast iron |

| Cylinder diameter | 92 mm |

| Pistons | original |

| Crankshaft | lightweight |

| Piston stroke | 86 mm |

| Fuel | AI-92/A-76 |

| Environmental standards | Euro-3/Euro-0 |

| Fuel consumption | highway – 8.3 l/100 km combined cycle 11.5 l/100 km city – 13.5 l/100 km |

| Oil consumption | maximum 0.3 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 10W30, 10W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for ZMZ 406 by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 6.1 l |

| Operating temperature | 90° |

| ICE resource | stated 150,000 km real 200000 km |

| Adjustment of valves | hydraulic pushers |

| Cooling system | forced, antifreeze |

| Coolant volume | 10 l |

| water pump | with plastic impeller |

| Spark plugs for ZMZ 406 | domestic A14DVRM or A14DVR |

| Spark plug gap | 1.1 mm |

| Valve train chain | 70/90 with shoe or 72/92 with sprockets |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | 7 offset holes, 40mm inner diameter |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | Goetze, light intakes, dark graduation |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min -1 |

| Tightening force of threaded connections | spark plug – 31 – 38 Nm flywheel – 72 – 80 Nm clutch bolt – 19 – 30 Nm bearing cap – 98 – 108 Nm (main) and 67 – 74 (rod) cylinder head – three stages 40 Nm, 127 – 142 Nm + 90° |

The factory manual contains a more precise description of the parameters:

- ZMZ 4063.10 – carburetor, compression ratio 8 for operation on A-76 fuel, power 110 hp. s., torque 186 Nm, weight 185 kg;

- ZMZ 4061.10 – carburetor, compression ratio 8 for A-76 gasoline, power 100 hp. s., torque 177 Nm, weight 185 kg;

- ZMZ 4062.10 – injector, compression ratio 9.3 for AI-92 fuel, power 145 hp. s., torque 201 Nm, weight 187 kg.

Design Features

Officially, the ZMZ 406 engine became the third after 24D and 402 in the line of power drives of the Zavolzhsky plant. Received microprocessor ignition, DOCH gas distribution circuit with a two-stage chain drive.

The developers still used an in-line engine design with 4 cylinders, but there were two camshafts, they are located on top, inside the cylinder head. The compression ratio of the internal combustion engine was increased by the plant designers to 9.3 in the basic version 4062.10 due to the central location of the spark plug inside the combustion chamber.

Reliability is increased due to a cast-iron cylinder block without liners, a reduction in the piston stroke to 86 mm and the weight of the entire ShPG group. Connecting rods with bolts, crankshaft and piston rings made of high-strength materials, so major repairs are required less often.

The chain tensioners are automatic, double-acting - preloaded by a spring during hydraulic operation. The degree of oil purification is increased by installing a full-flow disposable filter. A separate V-belt drive is provided for attachments. The ECU firmware corresponds to SOATE, ITELMA VS5.6, MIKAS 5.4 or 7.1 versions

List of internal combustion engine modifications

Initially, the engine was designed to be fuel-injected, so version 4062.10 is considered the basic one. The need for carburetor modifications 4061.10 and 4063.10 arose later. They were installed on Gazelle, so while maintaining the volume of the combustion chambers, it was necessary to reduce the owner’s operating costs. To do this, ZMZ management lowered the compression ratio in order to switch the engines to cheaper A-76 fuel.

A reverse modernization was made with motors 4061 and 4063:

- reduced power and torque;

- XX speed became 750 min -1 instead of 800 min -1 ;

- Maximum torque is achieved at 3500 rpm, rather than 4000.

Everything else mounted is located in the same places without changes. Some parts are interchangeable, with the exception of the cylinder head and piston.

Advantages and disadvantages

A negative feature of the ZMZ 406 power drive is the low quality of casting and poor technical solutions:

- high oil consumption due to unfinished ring design;

- low timing life of the drive due to the tensioner, collapsible block star and bulky design as a whole.

Fuel consumption is high, but this is typical for most truck engines.

But vibrations are reduced, the cylinder head does not unscrew during operation, the gasket does not need to be constantly changed, and the nuts do not need to be tightened. The maintainability of all components is high, the design itself is reliable and simple. The user is spared the need to adjust valve clearances every 20,000 miles.

List of car models in which it was installed

Since the ZMZ 406 engine has three versions, each of them was used on specific models of the car manufacturer GAZ:

- ZMZ 4062.10 – GAZ 31054 Luxury configuration; GAZ 3102 (1996 – 2008);

- ZMZ 4061.10 – GAZ 3302, 33023, 2705, 3221;

- ZMZ 4063.10 – GAZ 3302, 33023, 2705, 3221, 32213, 322132, 32214, SemAR 3234, Ruta, Bogdan and Dolphin.

In the first case, the engine characteristics were suitable for the urban cycle of executive cars of officials and governments. Carburetor modifications reduced the operating budget of Gazelle vans, utility vehicles and trucks.

Maintenance schedule ZMZ 406 2.3 l/100 l. With.

According to the manufacturer's requirements, the ZMZ 406 engine is serviced in the following order:

- inspection of the timing chain after 30,000 miles, replacement after 100,000 km;

- oil and filter change after 10,000 km;

- replacing the coolant approximately every two years or 30,000 mileage;

- recharging the battery every autumn, replacing after 50,000 km;

- spark plugs last for 60,000 miles;

- the fuel filter becomes unusable after 30,000 km, the air filter - 20,000 km;

- Ignition coils fail after 50,000 miles.

The manufacturer recommends using high-quality lubricant for engines so that the hydraulic compensators and oil pump work properly. Initially, the cooling system has weak spots– radiator and thermostat. All attachments are highly durable, with the exception of the pump, the polymer rotor of which lasts about 30,000 km. Due to the heavy weight of the engine, it is very difficult to carry out major repairs yourself in a garage without a hoist.

Review of faults and methods for repairing them

By virtue of design features The ZMZ 406 motor bends the valve only when the chain jumps. Moreover, they are damaged by each other (intake and exhaust during simultaneous lifting), and not by the pistons. If the chain breaks, such a problem will not happen.

Since the internal combustion engine device is partially copied from the SAAB, and the design of the ZMZ 402 is partially preserved, it is characterized by malfunctions:

| High speed XX | 1) sensor failure 2) there is no contact of the XX regulator 3) crankcase ventilation hoses are torn | 1)replacement of sensors 2)restoring contact 3)replacement of hoses |

| Cylinder failure | 1) ECU malfunction 2) coil failure 3) breakdown of the spark plug tip 4) nozzle failure | 1)replacement of the control unit 2) coil repair 3)replacement of tip 4) repair/replacement of nozzle |

| Unstable operation of the internal combustion engine | 1) air leak 2)water in the fuel tank | 1) restoring tightness, replacing gaskets 2) draining gasoline, drying the tank |

| The engine does not start | 1) failure of the ignition system 2) fuel supply is interrupted | 1)replacement of coil, contact 2) replacing the filter, pressure reducing valve, adjusting the phases, replacing the fuel pump |

Due to the large diameter of the pistons, the block and cylinder head are sensitive to overheating, so the level of working fluids (oil and antifreeze) should be checked regularly.

Engine tuning options

Initially, the ZMZ 406 engine allows you to increase the power on your own to 200 - 250 hp. With. Mechanical tuning is used for this:

- installation of a zero resistance filter;

- reduction of air temperature in the intake tract;

- replacement of the standard K-16D carburetor with Solex (adjustment with quality/quantity screws is required).

For Gazelle minibuses and trucks, turbo tuning is ineffective, since the service life of the diesel engine is reduced and fuel consumption increases sharply.

Thus, the injection modification ZMZ 4062.10 and carburetor versions 4061.10, 4063.10 are developed on the basis of the Swedish H series engine for trucks and executive cars. Tuning is allowed, primarily to increase torque.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

The ZMZ 406 engine was being developed to replace the 402 engine simultaneously with the design of the GAZ-3105 car for the government. However, these new Volgas were equipped with them only for the last batch, which had to be urgently sold due to the removal of the cars from production.

ICE ZMZ 406

The basis was taken from the ZMZ 402 (equipment) and the H series engine from the manufacturer SAAB (design solutions). As a result, with the same volume of 2.3 liters, the power drive provided 177 Nm of torque instead of the prototype’s 210 Nm and 100 hp. With. power instead of the expected 150 hp, like the Swedish internal combustion engine. The injection system, which later replaced the carburetor, was able to improve the situation slightly - 201 Nm and 145 hp. s., respectively.

Carburetor version ZMZ 4061.10

Carburetor version ZMZ 4061.10

For the first time, several advanced technical solutions for that time were used in the engine of the manufacturer ZMZ:

- two intake and two exhaust valves per cylinder;

- electronic ignition and injection systems;

- diagram of the DOCH gas distribution mechanism with two overhead camshafts;

- hydraulic pushers instead of adjusting the thermal clearance of valves with gaskets.

Valve tappets

Valve tappets

After the changes made, the technical characteristics of ZMZ 406 correspond to the values given in the table:

| Manufacturer | ZMZ |

| Engine brand | 406 |

| Years of production | 1997 – 2008 |

| Volume | 2286 cm 3 (2.3 l) |

| Power | 73.55 kW (100 hp) |

| Torque moment | 177/201 Nm (at 4200 rpm) |

| Weight | 192 kg |

| Compression ratio | 9,3 |

| Nutrition | injector/carburetor |

| Motor type | in-line petrol |

| Ignition | switchboard |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 2 pcs. DOCH scheme |

| Cylinder block material | cast iron |

| Cylinder diameter | 92 mm |

| Pistons | original |

| Crankshaft | lightweight |

| Piston stroke | 86 mm |

| Fuel | AI-92/A-76 |

| Environmental standards | Euro-3/Euro-0 |

| Fuel consumption | highway – 8.3 l/100 km combined cycle 11.5 l/100 km city – 13.5 l/100 km |

| Oil consumption | maximum 0.3 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 5W40, 10W30, 10W40 |

| Which engine oil is best by manufacturer | Liqui Moly, LukOil, Rosneft |

| Oil for ZMZ 406 by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 6.1 l |

| Operating temperature | 90° |

| ICE resource | stated 150,000 km real 200000 km |

| Adjustment of valves | hydraulic pushers |

| Cooling system | forced, antifreeze |

| Coolant volume | 10 l |

| water pump | with plastic impeller |

| Spark plugs for ZMZ 406 | domestic A14DVRM or A14DVR |

| Spark plug gap | 1.1 mm |

| Valve train chain | 70/90 with shoe or 72/92 with sprockets |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | with check valve |

| Flywheel | 7 offset holes, 40mm inner diameter |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | Goetze, light intakes, dark graduation |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min -1 |

| Tightening force of threaded connections | spark plug – 31 – 38 Nm flywheel – 72 – 80 Nm clutch bolt – 19 – 30 Nm bearing cap – 98 – 108 Nm (main) and 67 – 74 (rod) cylinder head – three stages 40 Nm, 127 – 142 Nm + 90° |

The factory manual contains a more precise description of the parameters:

- ZMZ 4063.10 – carburetor, compression ratio 8 for operation on A-76 fuel, power 110 hp. s., torque 186 Nm, weight 185 kg;

- ZMZ 4061.10 – carburetor, compression ratio 8 for A-76 gasoline, power 100 hp. s., torque 177 Nm, weight 185 kg;

- ZMZ 4062.10 – injector, compression ratio 9.3 for AI-92 fuel, power 145 hp. s., torque 201 Nm, weight 187 kg.

ZMZ 4063.10

ZMZ 4063.10  ZMZ 4062.10 injector

ZMZ 4062.10 injector

Officially, the ZMZ 406 engine became the third after 24D and 402 in the line of power drives of the Zavolzhsky plant. Received microprocessor ignition, DOCH gas distribution circuit with a two-stage chain drive.

The developers still used an in-line engine design with 4 cylinders, but there were two camshafts, they are located on top, inside the cylinder head. The compression ratio of the internal combustion engine was increased by the plant designers to 9.3 in the basic version 4062.10 due to the central location of the spark plug inside the combustion chamber.

Gas distribution mechanism design

Gas distribution mechanism design

Reliability is increased due to a cast-iron cylinder block without liners, a reduction in the piston stroke to 86 mm and the weight of the entire ShPG group. The connecting rods, bolts, crankshaft and piston rings are made from high-strength materials, so major overhauls are required less often.

Timing chain tensioner

Timing chain tensioner

The chain tensioners are automatic, double-acting - preloaded by a spring during hydraulic operation. The degree of oil purification is increased by installing a full-flow disposable filter. A separate V-belt drive is provided for attachments. The ECU firmware corresponds to SOATE, ITELMA VS5.6, MIKAS 5.4 or 7.1 versions

List of internal combustion engine modifications

Initially, the engine was designed to be fuel-injected, so version 4062.10 is considered the basic one. The need for carburetor modifications 4061.10 and 4063.10 arose later. They were installed on Gazelle, so while maintaining the volume of the combustion chambers, it was necessary to reduce the owner’s operating costs. To do this, ZMZ management lowered the compression ratio in order to switch the engines to cheaper A-76 fuel.

Versions of the ZMZ 406 engine differ in combustion chambers

Versions of the ZMZ 406 engine differ in combustion chambers

A reverse modernization was made with motors 4061 and 4063:

- reduced power and torque;

- XX speed became 750 min -1 instead of 800 min -1 ;

- Maximum torque is achieved at 3500 rpm, rather than 4000.

Everything else mounted is located in the same places without changes. Some parts are interchangeable, with the exception of the cylinder head and piston.

Advantages and disadvantages

A negative feature of the ZMZ 406 power drive is the low quality of casting and poor technical solutions:

- high oil consumption due to unfinished ring design;

- low timing life of the drive due to the tensioner, collapsible block star and bulky design as a whole.

Fuel consumption is high, but this is typical for most truck engines.

But vibrations are reduced, the cylinder head does not unscrew during operation, the gasket does not need to be constantly changed, and the nuts do not need to be tightened. The maintainability of all components is high, the design itself is reliable and simple. The user is spared the need to adjust valve clearances every 20,000 miles.

Intake manifold injector

Intake manifold injector

List of car models in which it was installed

Since the ZMZ 406 engine has three versions, each of them was used on specific models of the car manufacturer GAZ:

- ZMZ 4062.10 – GAZ 31054 Luxury configuration; GAZ 3102 (1996 – 2008);

- ZMZ 4061.10 – GAZ 3302, 33023, 2705, 3221;

- ZMZ 4063.10 – GAZ 3302, 33023, 2705, 3221, 32213, 322132, 32214, SemAR 3234, Ruta, Bogdan and Dolphin.

GAZ Gazelle Farmer

GAZ Gazelle Farmer

In the first case, the engine characteristics were suitable for the urban cycle of executive cars of officials and governments. Carburetor modifications reduced the operating budget of Gazelle vans, utility vehicles and trucks.

Maintenance schedule ZMZ 406 2.3 l/100 l. With.

According to the manufacturer's requirements, the ZMZ 406 engine is serviced in the following order:

- inspection of the timing chain after 30,000 miles, replacement after 100,000 km;

- oil and filter change after 10,000 km;

- replacing the coolant approximately every two years or 30,000 mileage;

- recharging the battery every autumn, replacing after 50,000 km;

- spark plugs last for 60,000 miles;

- the fuel filter becomes unusable after 30,000 km, the air filter - 20,000 km;

- Ignition coils fail after 50,000 miles.

Repair of ZMZ 406

Repair of ZMZ 406

The manufacturer recommends using high-quality lubricant for engines so that the hydraulic compensators and oil pump work properly. Initially, the cooling system has weak points - the radiator and thermostat. All attachments are highly durable, with the exception of the pump, the polymer rotor of which lasts about 30,000 km. Due to the heavy weight of the engine, it is very difficult to carry out major repairs yourself in a garage without a hoist.

Review of faults and methods for repairing them

Due to its design features, the ZMZ 406 motor bends the valve only when the chain jumps. Moreover, they are damaged by each other (intake and exhaust during simultaneous lifting), and not by the pistons. If the chain breaks, such a problem will not happen.

Since the internal combustion engine device is partially copied from the SAAB, and the design of the ZMZ 402 is partially preserved, it is characterized by malfunctions:

| High speed XX | 1) sensor failure 2) there is no contact of the XX regulator 3) crankcase ventilation hoses are torn |

1)replacement of sensors 2)restoring contact 3)replacement of hoses |

| Cylinder failure | 1) ECU malfunction 2) coil failure 3) breakdown of the spark plug tip 4) nozzle failure |

1)replacement of the control unit 2) coil repair 3)replacement of tip 4) repair/replacement of nozzle |

| Unstable operation of the internal combustion engine | 1) air leak 2)water in the fuel tank |

1) restoring tightness, replacing gaskets 2) draining gasoline, drying the tank |

| The engine does not start | 1) failure of the ignition system 2) fuel supply is interrupted |

1)replacement of coil, contact 2) replacing the filter, pressure reducing valve, adjusting the phases, replacing the fuel pump |

Due to the large diameter of the pistons, the block and cylinder head are sensitive to overheating, so the level of working fluids (oil and antifreeze) should be checked regularly.

Engine tuning options

Initially, the ZMZ 406 engine allows you to increase the power on your own to 200 - 250 hp. With. Mechanical tuning is used for this:

- installation of a zero resistance filter;

- reduction of air temperature in the intake tract;

- replacement of the standard K-16D carburetor with Solex (adjustment with quality/quantity screws is required).

Tuning ZMZ 406

Tuning ZMZ 406

For Gazelle minibuses and trucks, turbo tuning is ineffective, since the service life of the diesel engine is reduced and fuel consumption increases sharply.

Thus, the injection modification ZMZ 4062.10 and carburetor versions 4061.10, 4063.10 are developed on the basis of the Swedish H series engine for trucks and executive cars. Tuning is allowed, primarily to increase torque.

The power unit of the ZMZ-406 family is Gas engine internal combustion, which is produced by OJSC Zavolzhsky Motor Plant. Development began in 1992, and the motor entered mass production in 1997. It was the first to use a fuel injection system.

The ZMZ-406 engine was widely used and was installed on cars of the Gorky plant (GAZ-3102, 31029, 3110 and model range family "Gazelle")

The flagship of the family was the ZMZ-4062.10 engine with a volume of 2.28 liters and a power of 150 “horses”.

The ZMZ-4062.10 power plant is designed to be equipped with passenger cars and minibuses. And the ZMZ-4061.10 and ZMZ-4063.10 motors are for equipping light-duty trucks.

Engine Description

Previously, the engine was designed for newfangled power and ignition systems, which were controlled by a microprocessor.

This engine was the first to be equipped with four valves per cylinder, with hydraulic lifters and two camshafts with a double chain drive. An electronic fuel supply system and electronic ignition were also installed.

The four cylinders have an in-line arrangement, a water jacket and controlled fuel injection.

The operating order of the pistons is: 1-3-4-2.

The ZMZ-406 injector runs on A-92 gasoline. Previously, a carburetor version of the 4061 engine was produced, which ran on seventy-sixth gasoline. It had limitations in terms of release.

The unit is unpretentious in maintenance. It has a high degree of reliability. Later, on its basis, ZMZ-405 and 409 units were developed, as well as a diesel version of the engine labeled ZMZ-514.

The disadvantages of the engine include the bulkiness of the gas distribution mechanism drive, which is explained by its low quality execution and a number of technological shortcomings.

Technical characteristics of ZMZ-406

This power unit was produced from 1997 to 2008. The cylinder crankcase is made of cast iron and has an in-line position of the cylinders. The engine weight is 187 kilograms. Equipped with a carburetor fuel supply system or an injector. The piston stroke is 86 millimeters, and the cylinder diameter is 92 millimeters. At the same time, the engine displacement is 2286 cubic centimeters and is capable of developing a power of 177 “horses” at 3500 rpm.

Carburetor engine

The ZMZ-406 carburetor (402nd engine) has been produced since 1996 and has managed to establish itself as a simple and reliable unit. This device develops a power of 110 horsepower. The fuel consumption of a car with this engine often depends on driving style and operating conditions. The power system of the carburetor unit is quite reliable. With timely maintenance and normal operation, using high-quality lubricants and gasoline, it can travel up to 500 thousand kilometers without serious breakdowns. Of course, with the exception of boring the crankshaft, which is necessary for this unit once every 250 thousand kilometers.

Ignition system

On ZMZ-406 engines, ignition is carried out by igniting the fuel mixture using a microprocessor system. For all engine operating modes, the electronics sets the required ignition timing. It also performs the function of adjusting the working process of the forced idle economizer. Due to the operation of this system, the engine is distinguished by its high economic performance, exhaust gas toxicity standards are monitored, the moment of detonation is eliminated and the power of the power unit is increased. On average, a GAZelle car consumes about 8-10 liters of gasoline per 100 kilometers under average loads. However, if you convert it to propane or methane, the “appetite” of the machine almost doubles.

Ignition diagnostic mode

When the car ignition is turned on, the ZMZ-406 engine diagnostic system automatically comes into operation (the ZMZ-405 carburetor is no exception). The fact that the electronics are working properly is indicated by a light sensor. It should go out when the engine starts.

If the diode continues to light, this indicates a malfunction of the elements and parts of the electronic ignition system. In this case, the breakdown should be repaired immediately.

Injection motor

In terms of technical characteristics and components, an engine with an injection power system is not very different from the carburetor analogue of the 405 model.

With proper operation, this unit is no less reliable and practical than with a carburetor, and in addition has its own advantages:

- Stable idle speed.

- Low level of harmful emissions into the atmosphere.

- The efficiency of the ZMZ-406 injector is significantly higher than its analogue with a carburetor, since fuel mixture supplied in a timely manner and in the required quantity. Accordingly, fuel savings are obvious.

- Improved fuel economy.

- Does not require prolonged engine warm-up in winter.

The only disadvantage of an injection engine is the high cost of repair and maintenance of the system.

It is not possible to carry out diagnostic and repair work without special equipment and diagnostic stands. Therefore, implement do-it-yourself repair The injector of the ZMZ-406 engine is quite a troublesome matter. Often, when breakdowns occur in the injection system, a car owner has to use the services of specialized centers for servicing fuel equipment, which can be expensive and take quite a long time. In order to encounter this problem as rarely as possible, it is necessary to promptly replace fuel filters and refuel the car with high-quality gasoline.

Block head

All engine modifications were equipped with one head, which complied with Euro 2 requirements. With the introduction of additional Euro 3 requirements, it was refined and improved. It is not interchangeable with the previous model.

The new head does not have idle system grooves; now their functions are assigned to an electronically controlled throttle. The front wall of the part is equipped with holes for attaching the protective chain cover, and on the left side there are ebbs for mounting the intake system receiver brackets. The part has pressed cast iron inserts and valve guides. The latter do not require periodic adjustment, since they are driven by cylindrical pushers with hydraulic compensators. The modernized ZMZ-406 head has decreased in weight by 1.3 kilograms. When installing it on the engine, use a metal multilayer head gasket.

Cylinder block

By improving the ZMZ-406 engine, engineers were able to modify the crankcase and modernize the casting process. Thus, it was possible to equip the block with ducts in the casting between the cylinders. Thanks to this, this element has become rigid, and the head is fastened using deeper threaded holes and elongated bolts. In the lower part of the crankcase there are ebbs that form the crankshaft supports along with the main bearing caps. The covers are cast from cast iron and are attached to the block with bolts.

Camshaft

The ZMZ-406 camshaft is made by casting cast iron, followed by processing and hardening. The shafts are driven by chain transmission. The engine has two shafts, the cam profiles of which are the same size.

The axial displacement of the cams is one millimeter relative to the hydraulic pushers. This factor promotes the rotation of hydraulic drive elements when the engine is running, which significantly affects the wear of the working surface of the pusher and makes it uniform.

The chain drive of the shafts has hydraulic tensioners that operate from oil pressure in the lubrication system. The parts act on the chain directly through plastic shoes that are attached to the axles. After modernization, on ZMZ-406 engines, sprockets were used instead of shoes to increase practicality and durability. The latter are fixed on rotary arms. The sprocket mounting axles are interchangeable with the shoe axles. Instead of an extension of the upper chain tension shoe axis, they began to use a spacer, which is fastened to the block with bolts.

The ZMZ-406 engine is equipped with camshaft drive chains. It is not possible to replace them with chains that were installed on earlier versions of motors.

Pistons

They are cast from aluminum alloy and have grooves for two compression rings and one oil scraper ring. During operation, the piston crown is cooled by oil through an oil nipple in the upper end of the connecting rod.

Spherical working surface of the upper compression ring has a layer of chrome coating, which contributes to better grinding of the ring. The second element is coated with a layer of tin. The oil scraper ring is of a combined type; it consists of an expander and two steel discs. The piston is attached to the connecting rod using a pin fixed to two corkscrew rings.

Crankshaft

Cast from cast iron with subsequent processing and hardening of the surface of the journals with high frequency currents. It is installed in the block on five main bearings.

The movement of the crankshaft according to the axis is limited by corkscrew half-rings, which are located in the flow grooves of the support and the cover of the third main bearing. There are eight counterweights on the shaft. A flywheel is attached to the rear of the shaft, in the hole of which a spacer sleeve and a rolling bearing of the gearbox input shaft are pressed.

Oil

The ZMZ-406 power plant is equipped with a combined lubrication system. Under the influence of pressure, the process of lubrication of the piston pins, connecting rod and main bearings of the crankshaft occurs, the support points of the camshafts, the hydraulic valve drive, the intermediate shaft and the driven gear of the oil pump are lubricated. All other parts and elements of the motor are lubricated by spraying oil.

The oil pump is gear type, has one section and is driven from the intermediate shaft through helical gears. The lubrication system is equipped with an oil cooler and a full-flow cleaning filter.

Closed crankcase ventilation with forced exhaust of gases.

So, we have provided a detailed description of all components, assemblies and engine systems. The ZMZ-406 diagram is in the photo above.