Homemade kayak made of pvc pipes. Do-it-yourself PVC pipe boat: photo, video

A do-it-yourself PVC pipe boat is a simple design. Its manufacture will cost quite inexpensively, but you can get a lot of pleasure in the summer swimming season. You can make such a structure from plastic materials on your own. It's not a difficult job.

PVC pipe is the most convenient option for designing products with your own hands. These products are perfectly fastened with glue or soldering.

Even when the boat is damaged during use, there is no need to be upset. Such a repair on your own will not be difficult. Using the same glue, they simply patch the damaged area.

To the above, it must be added that the construction of such a boat with your own hands is a very interesting job.

It's a good idea to first make patterns of reduced sizes, and glue such a design from ordinary plastic bags. With such work, you can “feel” the material, which means that working with full-scale dimensions will be much easier.

After working out the patterns, they are proportionally increased. Masters advise to check the compatibility of the blanks by completing the design in natural dimensions from polyethylene.

This, of course, will take extra time, but it's worth it. If any errors are made in the calculations, then this will be clear at the initial stage, and you will not have to spoil expensive materials.

A home-made boat made of PVC pipes confidently occupies a leading position among do-it-yourself crafts made from this material.

The home craftsman can turn the most ordinary plumbing blank into an original water craft on his own.

Work sequence:

- Frame. PVC blanks, with a volume of at least 2.7 cm, are cut into four parts. Two two meters and a half each (for the upper part), and two with dimensions of 2.7 m (for the lower part). These pipes will serve as the supporting part of the structure.

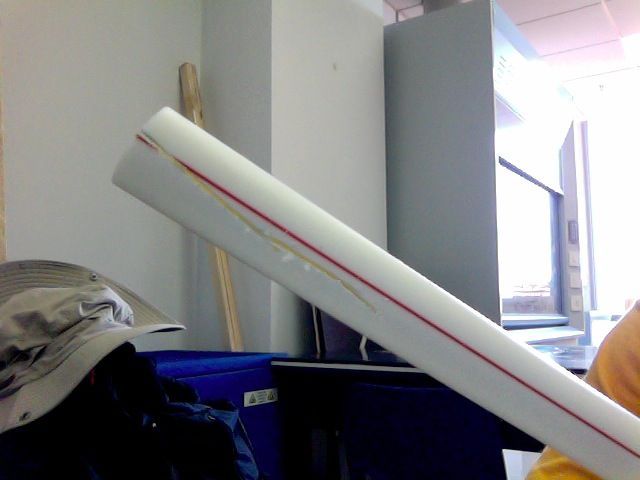

- Each end of these blanks should be cut at an angle of 45 degrees.

- Next, cuts are prepared slightly smaller with the following dimensions: 2 by 0.7 m, two by 0.6 m, two by 0.4 m and two by 0.35 m. These parts become supports for the boat frame.

- The support pipes are attached to the frame. The ends of the blanks must be fastened tightly, otherwise everything will fall apart and go to the bottom. For fastening, you can use adhesive tape or epoxy glue. For reliability, you can drill holes in the tubes with a drill and fix the structure with copper wire.

- being prepared wooden plank with holes, and is fixed on the bottom of the support frame. Plastic ties are used for fastening. The chair is attached to this board with the same fasteners.

- After that, the frame is covered with a tarpaulin. It must be waterproof. It is laid diagonally, and all protruding places are wrapped in the inside. The tarpaulin is attached to the frame with plastic clips. If there are rings on the tarpaulin, then you can attach it to the frame after holes are made in it for this. All folds must be stretched as much as possible. This will prevent unnecessary resistance while moving through the water.

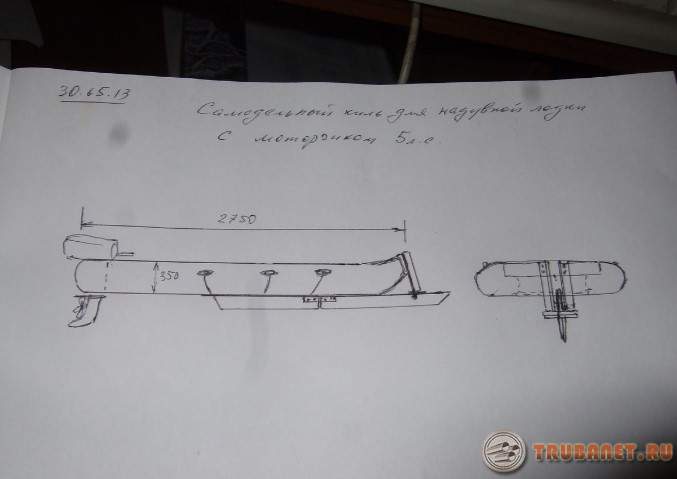

Keel

The keel made of a PVC pipe for a boat is used to endow the watercraft with increased stability. Most often, the keel is on options using an outboard boat engine.

The keel is installed so that its working part is in the bow area of the floating aid. From amidships to the stern, the keel goes to "no".

Another advantage of installing a keel is that it partially raises the bow of the structure. And this, in turn, prevents splashes from entering the boat during a large wave.

Keel making

A homemade keel for a boat made of plastic pipe is simple. All the material that goes into work is durable, light weight and low cost. For a punt, such a keel is ideal.

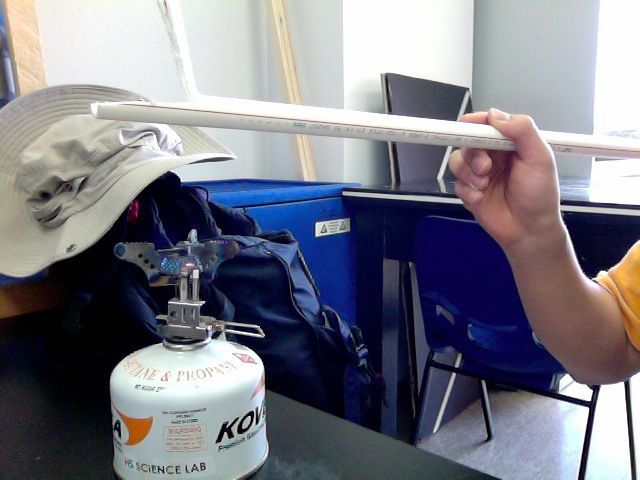

For manufacturing, a four-section plastic profile is taken, which is used when assembling windows and window sills. Two sleeves made of foam rubber are put on it, which are used to insulate pipe materials.

For manufacturing, a four-section plastic profile is taken, which is used when assembling windows and window sills. Two sleeves made of foam rubber are put on it, which are used to insulate pipe materials.

For convenience, the keel is cut in half and, when connected, a PVC pipe (approximately 0.5 m in size) is inserted into the middle of the tetrahedron.

The keel of such materials does not get wet, does not emit toxic substances, and is not destroyed by exposure to the sun's rays.

Also, for flat-bottomed structures of the watercraft, you can also make a home-made floor (slan). For work, you will need four boards, about 0.9 cm thick.

The width of all pieces should be equal to the distance from the side parts of the structure. All these pieces are fastened with tightening plastic clamps.

frame

The frame of the boat made of pvc pipes is the basis of the basics. The integrity of the structure will depend on its strength. How to build a frame correctly, you can find out on the provided videos.

If you approach this issue irresponsibly, then the constructed structure will fall apart at the first attempt to launch it into the expanses of water.

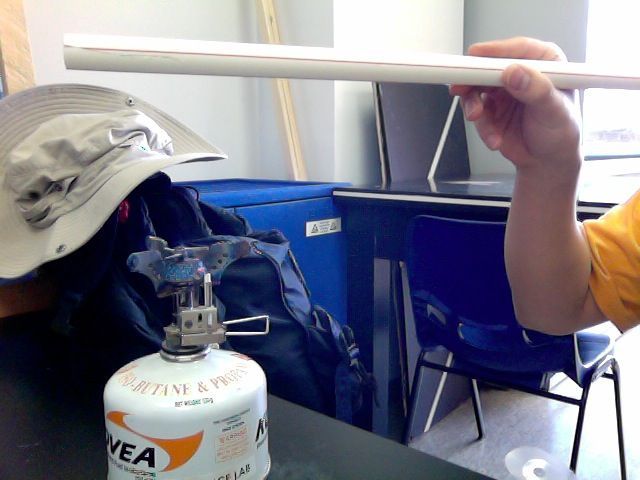

After detailed development and verification of the drawing, practical work on creating a frame can begin. You can fix the frame with the methods already proposed above, or you can use a soldering iron for plastic products to work.

Working with such tools is not difficult. Even a person who has no experience in this field can cope with these works. .

Buying for a one-time job in order to weld the frame, this tool is not recommended, justifying this with economic unprofitability.

It is better to use a rented device for attaching a frame made of plastic pipes. This service is offered by shops that sell soldering irons.

A frame made of blanks soldered with a soldering iron will last a long time. In addition, each joint of the frame will be characterized by high strength. So with your own hands you can make a very durable structure.

If any difficulties arise during work, then video materials will help to solve the problem of how to properly make a frame from PVC pipes.

Cart

Unlike a boat, which will take a little time to create, a PVC pipe boat cart is made quickly. It is intended for transporting a boat made of PVC pipes with an engine and adjacent cargo.

The presence of a trolley greatly facilitates the transportation of the boat. Having a do-it-yourself trolley, during transportation, you can do without outside help and stress.

The presence of a trolley greatly facilitates the transportation of the boat. Having a do-it-yourself trolley, during transportation, you can do without outside help and stress.

On the provided photo and video clips, there is an opportunity to see various options for these mechanisms. After considering them, you can choose the most suitable option for building your own.

Video

The dimensions of the trolley depend on the dimensions of the boat. And when calculating them, you need to keep in mind that the width of the cart should be such that the swimming facility is comfortably placed on it.

To create such a design with your own hands, you need to prepare a pipe with a volume of 32 mm. Experts recommend opting for products fiberglass reinforced.

You should also stock up on appropriate fasteners for pipes (couplings and crosses). You will also need a pair of wheels and a steel bar.

First, an axis is made of tubes with an inserted steel bar. Wheels are inserted on it and fixed with brackets. Further, a frame is made from the tubes, which is placed on supports above the axle.

On the frame, it is necessary to provide fasteners for the rope, with which the swimming device will be fixed on the trolley. That, in fact, is all the work.

Some more details

Now, how to make a boat out of pvc pipes is clear. This work will require a lot of patience, it will not take a short period of time, but in end result you can get great pleasure from such an addition to the rest on the water expanses as a great boat made by yourself.

For the convenience of swimming, you will need oars. They are also not difficult to make with your own hands. For this, not a thick PVC pipe is perfect.

It will take about two meters. Holes must be drilled at each end of the pipe. Then two strips 0.4 m long are cut out of acrylic.

These strips are attached to plastic tubes with self-tapping screws. Self-tapping screws are not advised to tighten very tightly, because acrylic can burst. And the lower part of the paddle is recommended to be slightly rounded.

Video

For greater stability of the product, outriggers can be attached to its side parts. Their role can be played by two large plastic bottles on remote slats.

There are pluses in such an addition, for example, the formation of free space for storing the catch or any other trifles. But, there are also disadvantages in such a solution, it is a little more difficult to row on such swimming facilities due to lack of space.

Awning

A real fisherman never quits fishing winter time, nor in bad weather. When fishing in the summer, an awning can protect afloat from the scorching rays of the sun and from heavy rain afloat. With such protection, the river walk will not be hopelessly spoiled.

Summer is coming and so is swimming season. It would be nice to make a simple boat using plastic pipes. It will take approximately one month to create such a boat, and a school swimming pool is suitable for testing it.

Step 1. Required materials

For boat:

plastic pipes (PVC) - 122.5 cm

plastic pipes (PVC) - 401.3 cm

wooden board - 1 × 0.5 m

plastic clips - 50 pcs.

adhesive tape - 2 rolls

foam block - 2 pcs.

foam rubber - 30 × 30 cm - 2 pcs.

nylon thread

chair - 1 pc.

For supports (optional)

wooden slats - 122 cm × 5 cm

bottles (for water) - 4 pcs.

Super glue

screws (for drywall) - 8 pcs.

For oars

aluminum pipe - 225 cm

acrylic sheet - 40×40 cm

bolts, nuts, washers - any size, 4 pcs.

Manufacturing instructions:

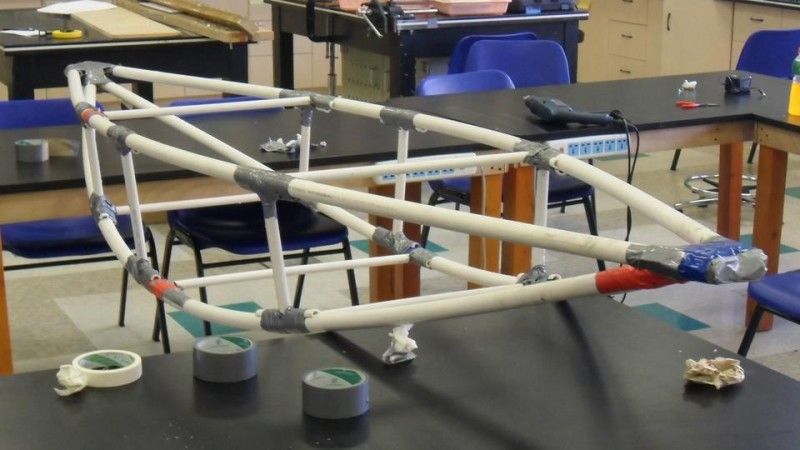

Step 2. Boat frame

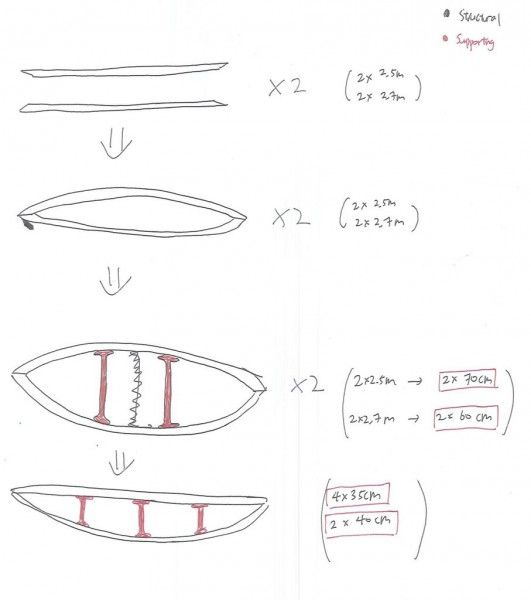

For the frame of the boat, it is necessary to cut the plastic pipes into 4 parts: (for the upper part) 2 × 2.5 m, (for the lower part) 2 × 2.7 m. These parts are the supporting frame of the boat. Each pipe must be cut at a 45 degree angle.

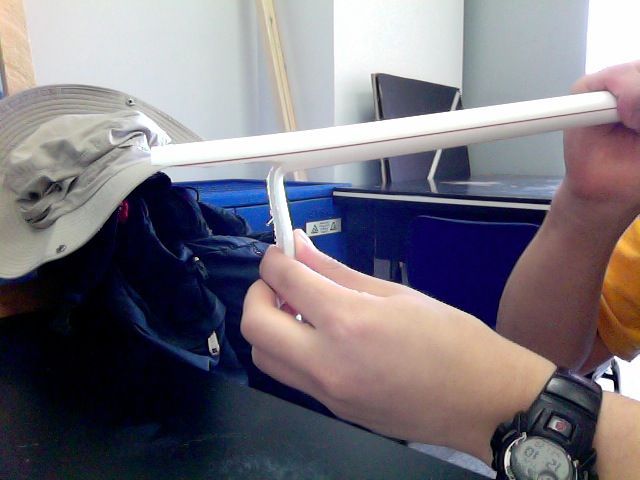

For the support part of the frame, you need to cut 1.3 cm of plastic pipe into 2 × 70 cm, 2 × 60 cm, 4 × 35 cm, 2 × 40 cm. The photo shows how to cut the support pipes on each side to secure them.

For the manufacture of the frame, it is necessary to connect the ends of two cut pipes of 2.5 m each with adhesive tape. They are fastened tightly "face to face" so that the boat does not break and drown. You can also use epoxy glue to better hold the frame parts together.

It is necessary to drill holes in the top and bottom of the frame, and then connect them with copper wire.

Frame support tubes need to be added.

Step 3: Attaching the Chair and Foam

The wooden board must be fixed to the bottom of the support frame using plastic ties. To do this, it is necessary to drill several holes in it. Also, several holes must be drilled through the chair and boards, and the chair must be fixed to the frame with zip ties.

Step 4. Sheathing the frame

In order to cover the frame with a plastic awning, it is important to first make sure that it does not let water through. To begin with, the kayak is turned over, and then covered with a tarpaulin diagonally, all the extra, protruding parts are laid inside the boat.

The tarpaulin is fixed with tapes on both sides and fastened with plastic clips to the frame. If the casing is with rings, then they can also be fixed to the frame; for this, holes must be made on the frame.

To avoid unnecessary resistance during swimming, it is important to straighten the folds of the skin as much as possible.

The foam at the bottom is added after fixing the skin, but carefully so as not to spoil it.

Step 5. Making the oar

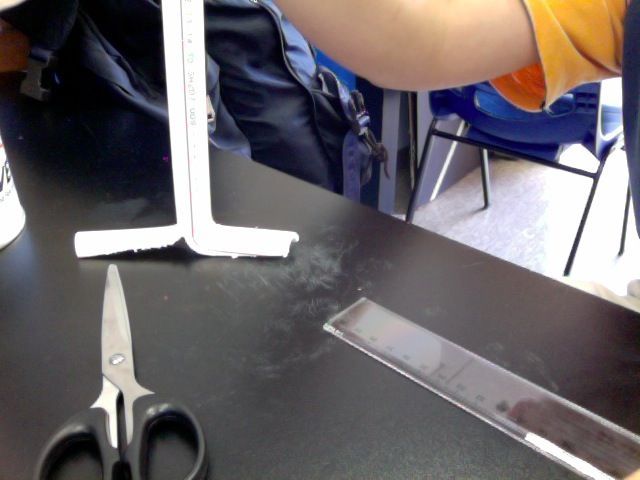

To make an oar, you need 2 meters of aluminum pipe, in which 2 holes are drilled from both ends, at a distance of 10 cm from each other. Cut out 2 pieces of acrylic measuring 20x40 cm and round off the edges.

Acrylic is fixed with nuts, bolts and washers, having previously drilled the appropriate holes on the pipe and plate. It is necessary to carefully and carefully tighten the nuts on the plate, because. acrylic may crack.

Step 6. Attaching the remote buoys

If the boat is unstable on the water, you can attach 2 bottles to the outriggers on each side. You can limit yourself to one side, also effectively.

The boat keeps well on the water, but it is difficult to row on it due to the lack of space for a rope, fishing line. Outriggers can serve as such additional storage space.

Step 7. First test

You can use the swimming pool for swimming.

As the test showed, the boat is very stable without outriggers, but it is very difficult to maintain balance at certain points.

Outriggers provide better stability. To shift the center of gravity, you can move the chair further from the bow of the boat, so the kayak will not tilt as much.

Thank you for your attention.

Time to go!

The dream of any avid angler is a light, maneuverable boat that is easy to transport to your favorite lake and go fishing for your own pleasure. In principle, you can make a similar compact folding PVC boat with your own hands and enjoy fishing.

The boat is assembled from polypropylene or PVC, therefore it weighs only 40 kilograms. The height of the boat sides is about 50 centimeters, and the width reaches 1.2 meters, and the total length of the boat is 3 meters 75 centimeters. Can be easily transported in the trunk of a car.

You can install a motor on the boat, and then it speeds up to 12 km / h (with a motor power of 3.5 hp). It takes about 10 minutes to assemble the boat on the shore. If the engine suddenly stalls, which happens quite often, then the boat slides easily on the oars.

Necessary Materials for PVC Boat

In order to make such a boat with your own hands, you will need polypropylene sheets, three boards, several hundred bolts, a bottle of silicone sealant, a jigsaw and a screwdriver. It takes about a week to assemble the model, but the result is worth it.Polypropylene is a sheet material used for 5mm pools. Firms involved in water tanks also sell - the price of 1m2 is about 750 rubles and more. This boat took 8m2 + wood for seats, mounts and a transom for the motor.

Boat dimensions can be smaller if solo fishing is expected.

From the experience of making PVC boats

You can use not bolts, but welding, but then in the event of a breakdown it will be difficult to replace the damaged section of the boat.

If bolts will be used in the assembly of the boat, then it is necessary to make an edging. Polypropylene is a fairly durable material, and it is simply impossible to bend it, but if you make an edging, then it will be easy to bend it. It is enough to make recesses of about 3 millimeters with an ordinary cutter.

You need to step back from the edge so that there is enough space for placing a 15 mm bolt with a washer.

Care must be taken, especially when the sheet is just beginning to be cut or at the end. These areas are critical because the cutter can slip and cut through the sheet.

The cut sheet can be easily bent, and its shape can be changed, no deformation of the material will occur. True, it is not advisable to use glue for attaching boat seams - it will leak anyway. Either bolts or welding will be required.

When you make a boat, you can start making anchors for pvc boats with your own hands. But more on that in the next article.

We wish you a pleasant pastime with a fishing rod. We are waiting for your feedback.

PVC is a modern material with a lot of positive qualities. It is quite inexpensive, light, strong, durable, resistant to different climatic conditions and environments. In addition, plastic pipes are easily and quickly connected, ensuring absolute tightness of the joints.

Due to this, the use of plastic pipes has gained wide popularity not only in the installation of water pipes and sewer systems. Of these, "craftsmen" make many useful "things" with their own hands, ranging from racks and drinking bowls to sledges and boats.

In this article, we will tell you about how you can quickly and inexpensively make a catamaran from plastic (do it yourself.

Article content

Why a catamaran?

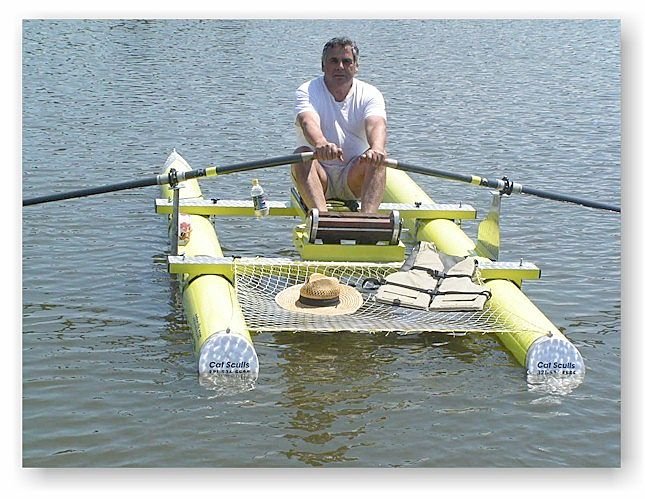

There are a lot of options for boats, as well as their purposes. For those who live near water bodies, and especially for those for whom overcoming a water barrier is a vital necessity, a catamaran is ideal. This type of vessel has many advantages. in front of kayaks, boats or yachts.

- for the manufacture of catamarans from plastic pipes, a minimum amount of material is required. In addition, the remnants of a recent installation of a sewer or water supply may well be used;

- the catamaran is light in weight, so it does not cause problems in matters of transportation;

- due to the design features - two cylinders connected by a deck, such a craft has high seaworthiness, strength, reliability and sufficient speed;

- the ability to accommodate the required number of seats;

- any type of engine can be installed on a catamaran.

What is a catamaran made of?

The catamaran has a large number of design features, in comparison with other watercraft.

That's why you need to know in detail its components, before proceeding with the drawings and installation work.

- The first and most important part of a catamaran is the floats. These are two chamber structures located on the sides of the craft. Their immediate task is to keep the ship afloat. Cylinders can be made of different materials, limiting the outer perimeter of the float. To do this, use a film from which inflatable balloons, polystyrene foam or PVC pipes are made.

- Connecting frame. It can be made of any materials, ranging from the same plastic pipes to wood or metal. The lighter the frame of the catamaran, the smaller the floats can be.

- Deck. This part is created to accommodate passengers, luggage and other things that will be transported by water.

- Steering wheel. The rudder function of any watercraft is performed by an underwater blade, which is installed parallel to the movement for direct movement, and is bent in one direction or another with the help of a rotary handle brought to the deck to turn.

- Oars, pedals, motor or any other device that sets the catamaran in motion.

Vessel size calculation

The diameter of the floats, as well as the width and length of the vessel, depend primarily on where and how it will be operated. The larger the crew is supposed to be and the more cargo will be transported, the larger the size of the craft and the diameter of the floats should be.

It is possible to increase the carrying capacity of the vessel by increasing the cross section of the cylinders or their length. The decisive factor in this situation is the volume of air inside the cylinders.

Optimal parameters for calculating floats, based on the crew and carrying capacity are as follows:

- a single catamaran should have a length of 2-3 meters with a cylinder cross-section of 0.3-0.4 meters;

- for the manufacture of a double vessel, cylinders 3.5-4 meters long with a diameter of 0.45-0.5 meters are used;

- three and four-seater boats have a length of up to 6 meters with a float diameter of 0.5-0.6 meters.

A catamaran with a length of more than 6 meters is not recommended, since it will lose its maneuverability almost completely. Although, if you are going to swim mainly in a straight line, there are no restrictions on the size of such a “boat”.

The larger the size of the vessel, the greater its maneuverability and stability, but less maneuverability. This applies to both its length and width.

The width of the catamaran, first of all, is determined by its purpose and the method of actuation. If you are building a catamaran for river rafting using the kayak principle, its width should not exceed 1.2 meters. Otherwise, the capture of water by oars becomes impossible. If it is planned to board rowers on cylinders, the width of the vessel can be increased up to 2 meters.

If the catamaran will be fishing or recreational and it is planned to be equipped with a sail, motor or blades with pedals, its width can be increased even more.

The width of the catamaran must be at least one and a half times less than its length.

Manufacturing procedure

To make a catamaran with your own hands, you need to decide on its purpose and, based on from this, calculate the dimensions. We will consider two options for the vessel: the simplest single-seater and a tourist raft based on a catamaran.

Single catamaran

We begin the manufacture of the simplest single-seat catamaran with the manufacture of floats. We take two pipes of the same diameter and length (based on the calculations above, we need plastic pipes for external sewerage with a diameter of 0.4 meters and a length of 2 meters). We fasten on one side of both pipes. This will be the back of the catamaran.

The front part, for greater patency and maneuverability, needs to be raised. To do this, we use two plastic knees with a bend of 120 degrees. We fasten them to the second end of the pipes and also close them with plugs.

When assembling cylinders, pay special attention to the tightness of the joints. The slightest depressurization can lead to the sinking of the ship in the water.

The floats are ready. You can start assembling.

To connect the floats into one "whole" catamaran, you can use anything. Suitable plastic pipes of small diameter, wooden bars, metal corners and more.

- We make cross-beams 1.2 meters wide from the material of your choice.

- We install the cylinders strictly parallel to each other so that the bends look up and in the same direction.

- We fix the transverse strips on top of the cylinders. For fastening, both clamps and self-tapping screws can be used, with which the transverse strips can be screwed to the floats for greater strength.

- We install any comfortable seat on the transverse beams, take the oars in our hands and row where we want.

Do-it-yourself single-seat catamaran made of plastic pipes (video)

tourist raft

The basic principles for the manufacture of these two boats with their own hands do not have much difference. The only difference is that the pleasure raft will obviously not be designed for one person. And even better, if it also fits a load in the form of provisions, an umbrella from the sun, clothing, dishes and other things.

- We make floats in the above way. But you should take a pipe with a diameter of 500-600 mm and a length of 6 meters. This will make it possible to make a stable and passable vessel, on which you can take a nap without worrying about the life of the crew.

- We make a solid frame measuring 6 * 2 meters. Since the frame must not only hold the cylinders in the correct position, but also serve as a platform for the deck, it is better to make it from metal corners.

- Clamps are tightened onto the pipes from which the floats are made, to which, in turn, the frame is attached with bolts.

- On the frame, flooring is made of boards.

This design allows you to install any propulsion device on the catamaran, from pedal-driven blades to gasoline engines.

In addition, such a platform allows you to fully sunbathe in the sun, catch fish, in general, have fun and fruitfully relax in a narrow circle of best friends.

In the modern world, do-it-yourselfers have a lot of inexpensive materials from which you can make a boat with your own hands.

In this article we will look at how to make a homemade boat out of PVC pipes.

The easiest way to make a boat out of PVC pipes is to assemble the frame of a home-made swimming device with adhesive tape and stretch a plastic film on top.

This way of assembling a boat with your own hands is very simple and does not require any tools, except perhaps a knife or a saw for cutting plastic pipes to size.

Watch the production video homemade boat from plastic pipes and films.

As you can see, there are practically no difficulties!

But the test of this boat afloat.

I must say that the not too adequate swimming qualities of this home-made boat lie entirely on the assemblers' handiwork.

In fact, all home-made boats using this technology have lawyer Yegorov's kayak in their prototype.

Only he approached the production seriously and the result he got was an order of magnitude better. It all depends on you!

You can not wrap a homemade boat with a film, but use a banner fabric. This will help to avoid leakage, and the strength characteristics with a tight-fitting boat with a banner fabric will increase by an order of magnitude.

Drawings of PVC pipe boats

The easiest way to get a drawing of a homemade PVC pipe boat is to use a 3D editor. So, for example, for AutoCAD there are special libraries with plastic pipes, fittings and fasteners. Using it, you can get a drawing of almost any homemade PVC pipe boat.

The second type of homemade PVC pipe boats is the manufacture using large diameter pipes.

Here is a video of testing such a homemade boat

Here it is already necessary to approach the manufacture with great labor costs.

The video below shows the process of making such a boat in a garage.

To connect PVC pipes, you will have to purchase a special extruder or make it yourself.

However, making such a boat is only half the time. The second part of your time will be spent on equipment homemade pvc boats from pipes with fittings, as well as the installation of a transom and seats.

It is worth talking about the price.

The cost of making a homemade boat made of PVC pipes of large diameter with your own hands depends heavily on the size. So, for example, a home-made boat 2.5 meters long at a cost price will cost 5-7 thousand rubles. And for a boat 5 meters long, it will take from 8 to 9 thousand rubles, while in the store, the cost for boats of this size with a hard bottom starts from 38 thousand for 2.5 meters and from 50 thousand for 5 meters.

As you can see, the economy of making a homemade PVC pipe boat is very justified.