How to make a boat motor with your own hands. Homemade plywood boat: materials, choice of tools, construction features, drawings, hull assembly and seam taping

Probably every fishing enthusiast has at least once thought about how to make a homemade boat. This is not an easy task, but it is still possible to make such a watercraft. Moreover, you don’t have to be an engineer; all that is required of you is a few hours of free time. And you will learn how they are made from our article today.

Manufacturing difficulties

Is it really difficult to make such a design with a minimum set of tools? As practice shows, even with such equipment, a homemade inflatable boat (or plywood) can be easily made in 3-4 hours. Due to the fact that all this work requires a minimum of time, you can make a boat even in the open air. Well, if the weather changes, you can always cover it with a tarpaulin or a piece of plastic film.

What are the benefits of homemade plywood boats?

Firstly, plywood is a light, durable and quite warm material. It is almost impossible to kill such a boat, and it does not weigh too much. Secondly, unlike rubber analogues, the space in a plywood boat is enough for several people (at the same time, inside, between the seats, you can fit all the necessary fishing gear). In store options, there is a catastrophic lack of free space.  Thirdly, being in wooden boat, you don’t feel any discomfort at all.

Thirdly, being in wooden boat, you don’t feel any discomfort at all.

Preparation of materials

The main material from which homemade boats are made is plywood. There are no difficulties in finding it on the market. Plywood is perhaps the most accessible and cheapest material for such work. And it’s very convenient to work with her.

Let's get down to business

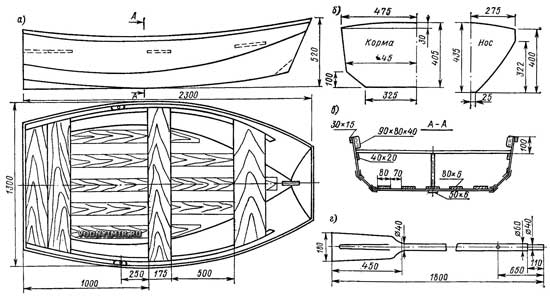

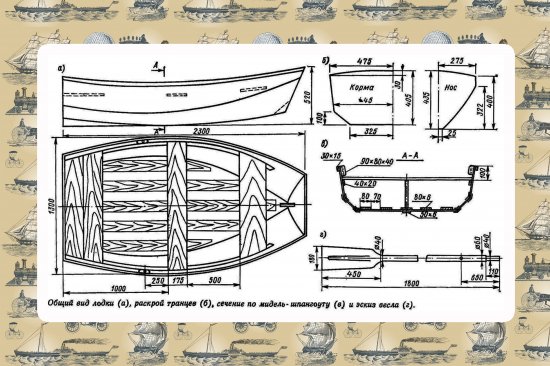

First of all, I would like to note that any work related to the independent production of any means (be it a tractor or something else, it doesn’t matter) must be carried out clearly according to a given scheme. In this case, you should have drawings of homemade boats on hand. In some cases, drawings can be replaced with a sketch drawing.

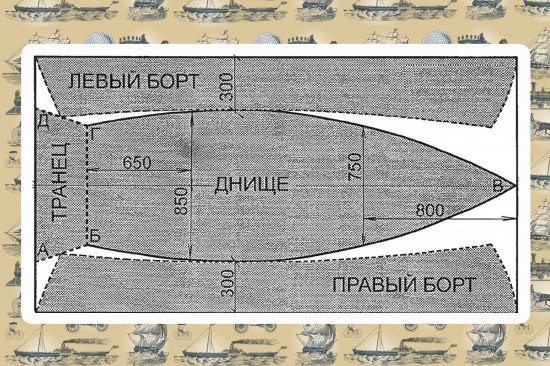

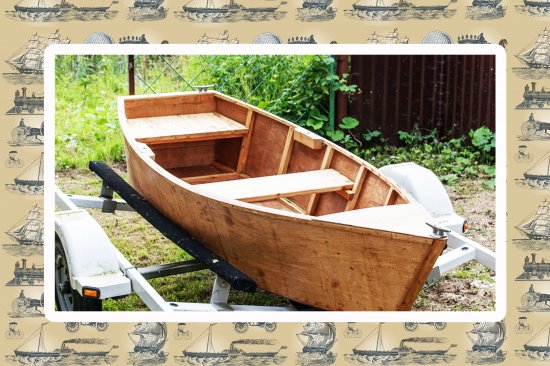

So, how are homemade boats made? To assemble the body, you will need to prepare dry boards 2.5 centimeters thick and a 6 mm sheet of plywood. The width of the boards for the stern and sides should be 30.5 centimeters. These are the most optimal sizes for a fishing boat. All other elements that are inside the structure (seats and spacers) are made from boards 2.5 centimeters wide. Moreover, the length of these parts is 86.4 centimeters. It must be taken into account that the dimensions of all these elements must be precisely maintained, since they are all attached to the boat hull only with self-tapping screws.

The manufacture of all parts and elements of this design does not cause any difficulties or difficulties. This is due to their simple geometric shape.

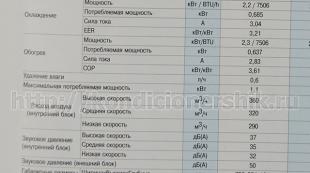

During the work, pay special attention to the fit of the joining surfaces and the frill of the boat. All joining edges must be carefully adjusted and have minimal gaps along their entire length. Either tinned or galvanized self-tapping screws are used as fastening elements. As for the dimensions of these fasteners, depending on the place of application, they can be as follows:

The bottom of the boat is made of a sheet of plywood 6 millimeters thick. But, since this part of the boat will be constantly exposed to water, to make the boat waterproof, additionally treat the joints of the hull and the bottom with VIAM-B/3 type glue and secure it with screws along the entire perimeter. If such a product is not available (“VIAM-B/3”), oil paint is quite suitable as an alternative. Although it does not have good adhesive properties and characteristics, it does provide a durable and waterproof coating. It is worth noting that the distance between the screws should be about 4 centimeters. External seams should be carefully taped with canvas or percale using AK-20. In order not to sink the bottom of the boat, a slatted grid is installed between the spacers (the cross-section of the slats is 5x2 centimeters).

Perhaps the most important step in building this craft is painting its plywood hull. How to do this correctly?

Before painting your boat, you need to prime it thoroughly. Here you will need to prepare a thick brush and natural drying oil, which will serve as a primer. In order for it to be better absorbed into the material, before applying it, preheat it to the starting temperature of boiling. It is applied not only to the outside, but also to the inside of the boat.

Immediately after applying this material to the wooden surface of the boat, it is strictly not recommended to begin painting it. First you need to wait a few minutes until the drying oil is completely absorbed into the wood. After the primer has completely dried, you can safely begin applying paint.

What colors should you choose for your boat?

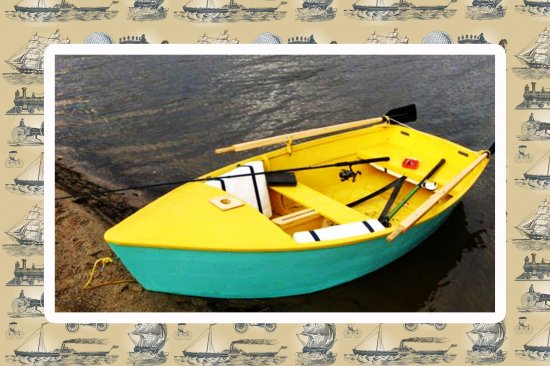

The most popular and, perhaps, harmonious combination will be the combination of white and red shades. Moreover, the first is applied to the lower part of the boat (to the waterline), and the entire remaining surface is covered in red. The inner part does not have to be covered with the same ones; the most popular option is a light green tone.

Application rules

It must be said that the paint that is sold in stores in tin cans and is often applied to wooden fences will not be the most the best option for our boat, which spends most of its time in the water. Therefore, we will receive it in a special way. So what needs to be done to achieve this? To obtain a red color you need to use zinc and  The resulting liquid should be diluted with clean drying oil. In this case, the calculation is made so that the boat can be painted 2-3 more times. Liquid paint has better properties; it spreads more easily, and therefore gives a more durable and even coating. When applying this product to the boat, wide soft brushes are used.

The resulting liquid should be diluted with clean drying oil. In this case, the calculation is made so that the boat can be painted 2-3 more times. Liquid paint has better properties; it spreads more easily, and therefore gives a more durable and even coating. When applying this product to the boat, wide soft brushes are used.

Some enthusiasts use nitro paints based on their high quality finish. However, we do not recommend using them for such boats, since they do not provide the necessary durability to the wood (accordingly, the structure becomes less durable and unsuitable for use every year).

Important points

If homemade ones are made motor boats, then an additional drawing of special fastenings for electrical or gasoline engine. However, a simpler and cheaper option would be to use regular oars. They are often made from 35mm birch boards. In this case, a spike with a handle is installed at the end of the spindle, and brass linings are applied to the edge of the blade. Next, the oar is primed and painted.

And finally, some statistics. As practice shows, the average service life of plywood boats is about 15-20 years. Neither plastic nor even their rubber competitors can boast of such durability.

The boat greatly expands the possibilities of the fisherman! This is a generally accepted fact, and we will not have a long debate here. Another question, ? It is clear that, depending on the conditions, boats of different designs will be relevant. Also, you can buy a boat, or you can make it yourself. About what there are homemade boats, about their advantages and disadvantages, about the feasibility self-made fishing boat - in this post.

Industrial boats are: inflatable (rubber, PVC) and rigid, usually awkward (made of plastic, wood, duralumin). What about homemade boats?

Make your own boat– it’s not an easy matter. They engage in independent boat building if there is stubbornly no money; if it is a remote region and there is nowhere to buy; if your hands are itching to make something, well, for example, a boat... In all other situations, it’s easier to just buy a suitable boat. Small inflatable - for small ponds and lakes; medium inflatable for medium lakes and rivers; a hard plastic one or a whole boat, if you have something to transport and plan to fish in large expanses of a river, reservoir or sea.

I have seen several designs of homemade boats, and I will tell you about them.

1. Rigid homemade boat made of plywood and wood. These are small boats, usually for fishing on small ponds and lakes. One- and a half-seater (if you do more, it will be too heavy). The contours are quite straight. Such a boat is carried on a “crown”, the top trunk of a car.

The frame and skin of the boat are assembled using self-tapping screws. The outer surface, sides and bottom are dried, primed and painted.

A plywood boat can be made in a wide variety of shapes. Clumsy rectangular shapes can, if you have the skills, be made smoother, more boat-like.

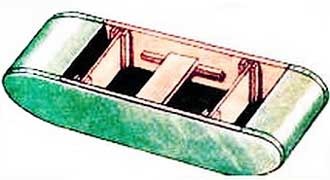

The awkward wooden boat shown in the drawing can also be made foldable, with a bottom made of rubberized fabric. The sides are hard, the bottom is soft. Make all cross braces removable. It will look something like this.

It is clear that such a boat will be more compact, and if necessary, it can be folded.

2. Homemade boat made of duralumin. In principle, it’s the same thing, only the boat’s hull is made of sheet duralumin. The joints are welded using argon welding.

3. The most interesting, in my opinion - folding duralumin boat. One of the spinners who lives next door uses this one.

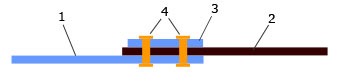

A total of 6 duralumin parts: bottom – 2 parts; each side - 2 parts. The elements are attached using elastic, durable rubberized fabric. The fabric is attached to the duralumin with a series of rivets, through an overlay.

1 – part side (bottom); 2 – strip of rubberized fabric; 3 – duralumin overlay; 4 – rivets.

My neighbor is not completely disassembling the boat. He just removes the spacers and folds the sides inward. If desired, you can also bend the structure across. And so, he places the boat on the top trunk of the car and tightens it with rubber bands. It comes out quite compact.

The transverse struts of such a boat consist of: a hard seat with a cushion and two wooden struts, the ends of which are protected by pieces of aluminum tubes that are inserted into special holes on the inner sides of the sides. Before fishing, the spacers and seat are inserted into place, ensuring rigidity of the structure.

Such homemade boat It’s comfortable because the bottom is hard – it’s good to sit on. The sides are not afraid of hooks and snags... The only disadvantages include some instability. Those. inflatable boat It is extremely difficult to turn over, and even if you scoop it up, it will remain afloat. In such a duralumin you need to behave carefully and avoid sudden maneuvers. By the way, my neighbor has been spinning from such a boat for many years and claims that it is more convenient than any inflatable one. I agree with him in many respects.

In addition, such a boat is assembled faster than an inflatable one. There is no need to download anything here.

It will be extremely useful for beginning fishermen. But not only that. I have collected the most important components of fishing skill and presented them clearly, systematically, “without water.”

Classic fishing on the river bank is, without a doubt, very convenient and in some ways even romantic. However, what to do if all the treasured fish are found far from the shore or in a place that cannot be reached except by water?

A boat is the best solution to this problem. But their cost in stores forces fishermen and tourists to sometimes show initiative and ingenuity, creating watercraft from literally nothing. What materials can you use to make a boat with your own hands?

Boat made of plastic bottles

An unusual but effective material for creating a boat can be commonplace plastic bottles. Since most The common volume of such containers is 2 liters, the most difficult stage in the design will be the collection of material.

In order to create a “bottle” boat, you will need the following materials:

- Bottles;

- Waterproof tape and glue;

- Knife or scissors;

- Wire;

- Plywood and crossbars made of wood or metal.

First of all, you need to thoroughly clean the bottles of stickers and labels. However, the most important thing to do at this stage is give plastic containers density and rigidity. The laws of physics will help with this. The bottles are placed in the refrigerator, where the lids are tightly screwed on, and then moved into a warm place. Thus, the air inside the bottles heats up and gives them an elastic shape. For greater reliability, it is advisable to secure the covers with waterproof glue.

First of all, you need to thoroughly clean the bottles of stickers and labels. However, the most important thing to do at this stage is give plastic containers density and rigidity. The laws of physics will help with this. The bottles are placed in the refrigerator, where the lids are tightly screwed on, and then moved into a warm place. Thus, the air inside the bottles heats up and gives them an elastic shape. For greater reliability, it is advisable to secure the covers with waterproof glue.

Installation of a boat from plastic bottles

Original logs are formed from pre-prepared bottles.

First step- connecting two bottles with their bottoms. To secure it, pull on a plastic ring cut from the middle of an empty bottle. This entire structure is coated with glue and tightly wrapped with tape in several layers.

The top parts of the next two bottles are cut off, after which the headless plastic is placed on the edges of the workpiece, again using glue and tape. This way, a reliable and sealed fragment of the future boat is obtained.

The further process consists of repeating the above steps and ends with the production of a log of the optimal size.

One float consists of eight logs, which are connected with strong wire, polyethylene and tape. Depending on preferences, the number of logs can vary up or down. The most important thing is to maintain balance and make the boat a reliable means of transportation.

The floats are mounted using crossbars made of wood or metal. The bottom of the boat can again be made of various materials. It can be plywood, plastic or metal sheet.

The final touch in making a boat can be covered with waterproof fabric or finishing with strong plywood followed by painting. This will improve the boat’s reliability and aesthetics.

Plywood boat

In addition to plywood as the main material, to create such a boat you will need:

- Jigsaw;

- Screwdriver;

- Saw;

- Hammer;

- Grinding device;

- Clamps and brushes;

- Wood;

Glue, resins, varnishes, drying oils, etc.

Installation of a plywood boat

The most acceptable option is large-sized plywood without defects in the form of delamination and cracks.

With the help of drawings, extremely careful marking of the material is carried out. If you make the slightest mistakes and discrepancies, making a boat without cracks will become impossible. To outline the plywood, you can use special patterns.

With the help of drawings, extremely careful marking of the material is carried out. If you make the slightest mistakes and discrepancies, making a boat without cracks will become impossible. To outline the plywood, you can use special patterns.

Next, each fragment is cut out with a saw and jigsaw. Particular attention is paid to the joining angles at the ends. The tailgate and frames will require installation of plywood in several layers to increase strength. If the design of the boat assumes the presence of a motor, then the tailgate supplemented with hardwood and glued with fiberglass.

Frames and transoms are fixed with tinned or galvanized screws. The bottom and sides are attached to the transoms using special glue and other materials for seams. It is advisable to strengthen the bottom of the boat with slatted flooring.

The seams are sealed with a special sealant, which contains epoxy resin and Aerosil in a 1:1 ratio. The fillets are stiffening ribs and are laid in the corners. All internal joints are treated with sealant, after which fiberglass is applied to them.

After drying the entire structure, frames, flooring on the bottom, seats and other planned elements are installed.

Before painting, all surfaces are degreased and sanded, then carefully treated with wood impregnation. If after all these actions the surface remains uneven and has cracks, a special putty comes to the rescue, and after drying, a primer.

Before painting, all surfaces are degreased and sanded, then carefully treated with wood impregnation. If after all these actions the surface remains uneven and has cracks, a special putty comes to the rescue, and after drying, a primer.

Usually used for painting marine enamel, hard brush or spray gun.

Folding boat made of duralumin

To create a folding boat you will need:

- Duralumin sheets;

- Rubberized fabric;

- Rivets and overlays;

- Wood;

- Metal scissors;

- Primer and paint.

Installation of a folding boat made of dualuminium

Duralumin is the most advantageous material for creating a folding boat. It is light and very durable, and to create a watercraft you need only six elements: two for the bottom and four for the sides.

Duralumin is the most advantageous material for creating a folding boat. It is light and very durable, and to create a watercraft you need only six elements: two for the bottom and four for the sides.

There are only three transverse struts in such a boat: one of them is the seat, the other two are struts made of wood with aluminum tubes at the ends. They are inserted into holes on the inner sides of the sides, which ensures the rigidity and reliability of the structure.

Before you start assembling the boat according to the drawings, it is recommended to recreate its prototype from cardboard. This will make it easier to eliminate all mistakes, and besides, such cardboard parts will also serve as patterns for duralumin.

All six parts of the folding boat are cut out with tin snips, then trimmed and hemmed. Holes for rivets are drilled in the joints every 2 centimeters. After that, the fragments of the boat are fastened with rivets, which are sealed with paint. Installation of duralumin can also be carried out using rubberized elastic fabric.

The gunwale and seats are made from any available wood and mounted with galvanized nails. Finally, the finished boat is primed and painted.

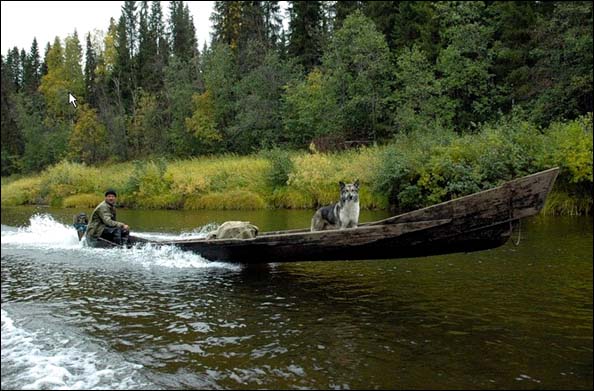

Despite the amazing abundance of commercially available designs small vessels, made from a wide variety of modern materials, there are still many hunters and amateur fishermen in the country who prefer homemade boats of their own construction.

Wooden boats

The most popular material for building homemade boats is still wood, or rather, thinly planed boards from certain types of wood. Almost every locality in our vast country has its own, time-tested designs of wooden boats, based on which more and more new ships are still being built. In any village standing on the shore of a lake, river or other body of water, today you can find simple wooden boats that have served their owners for many years both for fishing and for numerous household chores.

And yet, in recent years, the number of amateur boat builders using old-fashioned technologies has noticeably declined.

Modern technologies that have entered our lives make it possible to create more reliable, durable, strong and lightweight boat designs.

Using, for example, specially treated plywood, best bakelized, as well as modern polymer and protective materials, local craftsmen were quite capable of boats that, in their own way, operational characteristics greatly exceed the products presented by the industry. Such boats, as a rule, are in no way inferior in strength to metal boats made of aluminum and its alloys, in weight - even to especially light plastic boats, and in reliability - to boats made of PVC fabric.

The technology for building a modern wooden boat is quite simple and at the same time original. If we take into account only the general stages of construction, then building your own boat will look like this. The hull of the future boat is marked on sheets of moisture-resistant plywood, structural elements are cut out, frames are made, the bow and stern of the boat, as well as the transom if the boat will move under a motor.

The boat is assembled, its internal part is treated with antiseptics, foam sheets are installed on it to create an unsinkable effect, and then the entire structure is treated with epoxy resin, onto which several layers of fiberglass are glued. That's it, the boat is ready!

A homemade plywood-plastic boat, with the most basic care, will serve its owner for many years. If necessary, damaged parts of such a boat can be very easily repaired with a piece of fiberglass and epoxy resin. Such a vessel is very easy to transport in the trunk of a car, there is no fear of stones and sharp objects when fishing, it does not need to be dried after each fishing trip, and preparing it for winter storage is not difficult even for a teenager: two or three buckets of water are poured into the boat, the bottom is washed with a rag , and water pours out when the boat simply turns over. Simple, cheap and convenient!

Other fishing boat designs

There are countless options for building boats for recreational fishing! These could be, for example, light, for one person, some subtypes of kayak, riveted from a thin sheet of duralumin; the weight of such a boat does not exceed 10-12 kilograms! In some regions you can even find some semblance of boats, the basis of which is a wooden frame on which a tarred tarpaulin is stretched. However, in fairness it should be said that such designs were more typical of times when it was not easy to purchase a rubber boat!

The crazy thought of making a boat with his own hands has occurred to more than one fisherman. This is not easy to do, but it is quite possible. If desired, you can make a boat from plywood sheets.

Is it difficult to make a boat yourself?

Based on practice, we can safely say that it is possible to make a boat yourself with good tools within 4 hours of work.

A made plywood boat provides the following advantages:

Plywood is a good warm and light material;

Capacity is greater compared to rubber boats of the same dimensions;

There is no discomfort in a wooden boat.

You will need plywood. Finding the necessary plywood sheets and purchasing them will not be difficult. It is practical and convenient in work. Boats are homemade boats that are popular among fishermen.

Let's start implementing the project

You should always start by thinking through the overall design of the boat. Sketch out a sketch of the future boat. Prepare a dried 25 mm board and 6 mm thick plywood sheets. The stern and sides will require boards 30.5 cm wide. To make spacers and seats, boards with a width of 25 mm are taken. The length of the blanks is 86.4 cm. The dimensions must be observed, because the entire structure is held together with self-tapping screws. It is not difficult to make blanks according to given dimensions, since they are simple in geometry. Pay attention to the fit of the surfaces at the joints and the frill of the boat. Gaps are allowed in minimum values. Self-tapping screws are used as fasteners:

Galvanized;

Tinned.

Self-tapping screws with a thickness of 3 mm and a length of 18 and 26 mm will be used for the skin of the boat. For the remaining elements of the boat, self-tapping screws with a thickness of 4 and 5 mm and a length of 60 and 64 mm are used.

6 mm plywood will be used for the bottom of the boat. Ensure good waterproofing between the bottom and the hull elements. You can use sealant or special adhesives. If there is no glue, then oil paint will do just fine.

The screws are screwed in in increments of 4 cm. Carefully cover the seams on the outside with percale or cloth using AK-20 glue. To ensure the stability of the bottom of the boat against loads, install a sheathing of slats with a cross-section of 5x2 cm between the installed spacers.

Painting the boat

Painting the plywood hull of a boat is a very important and crucial moment. This is done correctly in the following sequence:

The body is primed. Drying oil should be natural. The drying oil is heated to boiling point and immediately removed from the surface of the stove. Using a thick brush, apply hot drying oil to all wooden elements of the boat hull along the outer and inner surfaces;

After priming with drying oil, you should wait until it is completely absorbed into the wood;

The boat is being painted.

A good color combination is white and red. Paint the bottom up to the waterline white. Above is the red color. The inside of the boat can be painted green in light tones.

The boat is in the water and therefore there are special requirements for paint. How to obtain paint with the required characteristics? The red color can be obtained by using red lead. White tones will be produced by lead or zinc white. Homemade boats should be treated well so that they do not rot.

It is diluted with natural drying oil in such a way that it is possible to apply another 2-3 layers of coating. Liquid paint adheres better to the surface, spreads well and forms an even and durable coating. Soft flute-type brushes should be wide. Some “masters” use nitro paints to paint boats. It is not advisable to do this. The service life of such a boat will be reduced by an order of magnitude.

Points to pay attention to

For a homemade motorboat, a place for mounting the engine is provided. It's cheaper and easier to use oars. The material for the oars is birch board 35 mm thick. A spike with a handle is installed on the end of the spindle. Brass plates protect the edges of the blades. After this, the paddle can be primed and painted. Homemade boats can be designed in different ways.

A plywood boat is superior in its “survivability” to its plastic and rubber counterparts. Such a boat will last from 15 to 20 years. Make your own boat and enjoy fishing.