What is a transom s. Transom for an inflatable boat. h. about a mounted transom

The transom looks like a rigid plate and is designed to mount an outboard motor.

Characteristics of a transom for an inflatable boat

In order to function properly, the transom must meet the following specifications:

- its width should be equal to the width of the ship or be slightly less;

- the ability to withstand significant loads, namely, from the motor used;

- technical compatibility with the design of the boat of a certain model;

- optimal height (usually 381 mm), due to which you can increase the speed of the boat.

Mounted transom for an inflatable boat

When purchasing a small inflatable boat, which is driven by oars, its owner may be tempted to install a motor. A removable transom for an inflatable boat will help solve this problem.

Outboard motors are mounted on the transom or back wall of the boat. There are four engine length sizes that are used on different types of boats. The shortest length is suitable for canoes and inflatable boats. A bass boat needs a longer shaft, and pontoon boats need a shaft size larger than a bass boat. Large shaft lengths are suitable for large sailboats and barges to propel them through the water with the propeller at the correct height. By measuring the length of your engine and the corresponding boat transom length, make sure the engine will operate at the correct height in the water.

The hinged transom is designed from the following parts:

- frame, for the production of which aluminum or steel profiles are used;

- transom board made of laminated moisture resistant plywood. The dimensions of the board that is included in the design of the transom, as a rule, vary from 280x280 mm to 300x300 mm.

Features of using a mounted transom

For the use of a mounted transom, a number of requirements have been established, which include:

Place the tip of the sword on top of the mounting clip bracket that secures it to the boat. Read the measurement at the bottom of the cavitation plate. The cavitation plate is a flat surface, horizontal above the propeller.

Write the shaft length in inches on paper with a pen. Read the measurement at the bottom of the transom. Boat transoms are shaped differently depending on the make and model. Measure each type of hull to the bottom center of the transom on each type of boat. Write down the length of the transom in inches on paper with a pen.

- limiting engine power to 3.5 horsepower and weight up to 15 kg;

- the need to ensure that the boat is always well inflated. If this condition is not observed, then the motor leg will strongly go under the boat.

Universal transom for inflatable boat

The universal transom is glued into the stern of the boat when it is glued together. As a rule, it is made from bakelite plywood, resistant to moisture. The height of the transom is not subject to adjustment and the engine model is selected for it.

Check outboard shaft length and transom length to match engine height when operating in water. check Short Shafts 15 to 19 inches long. Extended shafts are 25 to 29 inches long, and extra extended shafts are 30 inches and up. Long shafts from 20" to 24" long. . Starting from the hull, the crew makes their way to the transom change and to the workstation. So which best case for starters, than a legend? The original had a deeper pommel and very large reverse qings that needed a release mold.

Transom for inflatable boat "Hummingbird"

The transom for the Hummingbird inflatable boat is installed at the stern of the K250-K290 boats.

For its use of the transom, mounts are required, as well as a large Hummingbird handle on the stern of the boat. After acquiring the transom, you need to glue the fasteners and fix it on the boat.

Our main task was the condition of the hull. Melbourne Nautek Marine was trusted to manage the project as well as its reputation for fine individual work. Careful inspection of the hull revealed that the fiberglass structure was in a fairly good nickel finish, finding it rough and falling by. There were a few minor issues with the meat, but grinding revealed it was just hair gelcoat. However, Scotty Hurl grounded her right back and re-glazed the entire area with double offset cloth and epoxy for maximum repair strength.

So the transom is important element for any inflatable boat.

2.2. To inflatable boat designs.

A distinctive design feature of inflatable motor boats is the presence of a rigid transom, slant (flooring) and kilson (Fig. 2.69).

T knapsack .

We decided to further strengthen the hull where it met the deck, glazing both internal and external connections and creating a completely flat machine gun that would be finished off with a modern bumper strip. There are two accepted ways to do this. The first is to remove the entire back of the deck, providing access to the inside of the transom. This method allows the full integrity of the fiberglass outer skin to be maintained while working from the inside, but also creates some difficulty when replacing the deck and still requires all outer holes to be filled.

The second - and our chosen method - is to completely remove the transom from the outside, leaving only the inner fiberglass skin. Removing old plywood can be a tedious process and it may sound rough, but our first tool of choice is a chainsaw. He gets rid of the old plywood with minimal fuss, but special care should be taken.

The transom is a rigid plate with a length equal to or less than the width of the boat, and serves to mount the outboard motor. The transom must be harmoniously combined with the overall layout of the inflatable boat, have sufficient strength, withstand static loads from the weight of the motor and dynamic loads that occur during the operation of the inflatable motor boat (from propeller stop, vibration, shock when hitting underwater obstacles and when reversing).

After removing the clean surface, the surfaces must be completely dry to bond the fiberglass, epoxy and adhesive. Sheets of 25mm and 16mm marine ply were cut into shapes from cheap woodwork templates. Both sides of the marine layer were sealed with epoxy and the inner shell was sealed with three layers of 450gsm cut matte mesh. The 25mm sheet was set in place with a thick layer of epoxy to capture any cavities and then allowed to heal.

Ch. about a mounted transom

Any rough spots are sanded down to a smooth surface and a second layer of sealed 16mm plywood is glued in place and allowed to cure completely. Then come several layers of outer fiberglass. After all, the transom is probably the most important part of the entire hull. Finally, after a long and tedious process of wrapping and sanding, the transom was straight, true, and better than new. The original workstation was a very primitive thing.

Depending on the method of attachment to the hull, transoms are divided into two large groups: removable and glued. Removable transoms are used for boats of any shape. They are mainly found on boats with outboard motors up to 7.35 kW (10 hp). On boats with outboard motors up to 2.20kW (3HP), which are preferably used without slate and keelson, they add little to the boat's weight, assembly time, and package size.

two large groups: removable and glued. Removable transoms are used for boats of any shape. They are mainly found on boats with outboard motors up to 7.35 kW (10 hp). On boats with outboard motors up to 2.20kW (3HP), which are preferably used without slate and keelson, they add little to the boat's weight, assembly time, and package size.

We were initially concerned about adding extra weight of live lure to the back quarter of the port, but found the body to carry the weight well. We also removed molded rear seats to match the live bait that comes down to the floor. You need a lot of water and tons of flow to keep the big slugs alive for play fishing - a fault we often criticize with in many so-called offshore fishing rigs.

These six boats have unique or unusual transom designs. While anglers buying boats often focus on deck layouts and brand reputation, what matters to everyone is the design of a fishing boat's hull, and even its transom, can also speak volumes about its fishing and comfort.

The most common attachment for detachable transoms (Fig. 2.70) is to install them on a bracket mounted to the molded parts (usually two at the top for attaching the transom and two at the bottom to rest it against the side). On O-shaped and Y-shaped boats with an inflatable stern can, brackets are more often used in the form of a curved frame made of tubular or flat elements, repeating the curvature of the side and increasing the bearing area. Sometimes the brackets to which the transom is attached are made in the form of two tubular frames. The frame rods are curved along the side so that their ends at the stern of the boat are adjacent to the inflatable can or are located at some distance from it, providing an accurate installation of the outboard motor transom. The transom can be fastened to the hull of the boat by fastening or lacing it to the side or flooring with straps, braid or other flexible ties.

Consider that most fishermen spend a lot of time on the rear end of the cab, and it's easy to see just how cohesive a transom design can be: does it make it easy to run a rod over the outboards? Does it make it easy to boat or release fish? Does it create more usable fishing space? Does it properly balance heavy outboards? And in today's world where family fishing and boating have begun to outweigh hardcore fish on the minds of more and more buyers: what does transom design offer for those on board?

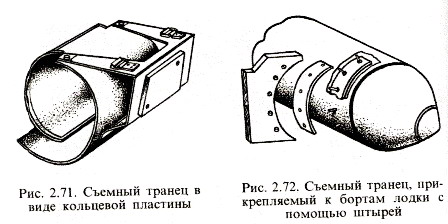

The original solution for the design of the transom for boats with a flat bottom is the execution of the bracket in the form of an annular elastic plate of cylindrical shape (Fig. 2.71),

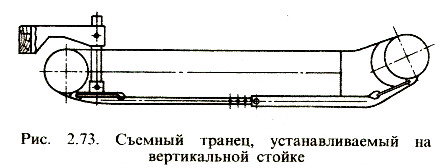

into which the aft compartment is inserted in an unfilled state. When the compartment is inflated inside the plate, the plate stretches, flexes outward and adheres tightly to the surface of the compartment. A transom board for mounting the outboard motor is installed on the annular plate. In some boat designs, there are transoms that are fully or partially inserted into pockets. Pockets are made of rubberized fabric or rubber in the form of molded parts. For U-shaped boats, removable transoms are usually located at a distance between the sides, and the cutouts for the transoms in height on both sides repeat the curvature of the side of the boat. The transoms are fastened with the help of molded parts, into the grooves or holes of which their ends are inserted (for example, on the Orion-8, Orion-9, Orion-15 boats). In the USA, a variant of the design of a removable transom has been proposed, which is attached to the sides of the boat using a group of pins. (Fig. 2.72) mounted on a patch glued to the board. On some models of inflatable boats by Semperit (Austria), the transom is pivotally attached to the flooring and rigidly fixed with spacers. When the shell of the boat is filled with air, due to the resulting pressure, the transom receives additional fixation. Sometimes the transom is attached to the sleigh using a vertical post, which makes it possible to adjust its height. (Fig. 2.73).

How to build a transom: description and photo

To take a look at the many fairly unique designs, we've identified six builders offering a variety of aft aesthetics. Here's what they told us about transoms. Kolkata 263 is a one of a kind design for the builder.

With the sea gate down, the entire aft deck of the catamaran is open and flat. Ellis says he measures 6 inches above the waterline. I have guys who will fight the fish on deck. Florida State University uses the boat for its shark and grasshopper research vessels, he says. One guy in Venice caught a 104lb wahoo. He was afraid that he would lose the fish, so he lowered the door, grabbed the fish by the tail and pushed it back.

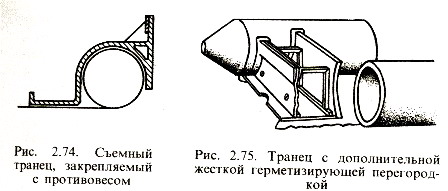

US patent No. 4.371.144 shows the design of a removable transom for low-power motors, the bracket of which, on one side, rests on the side, and on the other, on a horizontal platform in the bottom, on which a load is placed that counteracts the loads of the motor (Fig. 2.74). On boats with low power motors, the upper part of the transom is attached to a transverse tubular rod, the ends of which are fixed in molded parts on the sides (the lower part of the transom is attached to the deck of the boat).

While the 263 is the only Calcutta model to feature this transom, Ellis has been building it since the original idea came from Dr. Ernst Peebles, assistant professor of biological oceanography at the University of South Florida, and husband of marine artist Diana Reem Peebles.

What is a transom

He and I fish together,” says Ellis. He will call me and tell me his great ideas. He said the back of the boat should open like a pickup truck. The design has caught on with anglers, scuba divers and marine scientists. Berega inspected the vessel and told him that it was the only recreational boat that would pass the agency standards for an offshore commercial boat. “A stingy one and a half inches is not big enough to deplete the volume of water that could fill a boat,” he says. "If we were ever in that position, we could throw down the door and have the world's biggest Pomeranian."

The tightness of the cockpit of U-shaped boats, on which the described transom designs are used, is ensured by gluing to the sides and bottom up to the transom or behind it with a rigid (Fig. 2.75) or an elastic partition, the latter being also inflatable (Fig. 2.76).

The bottom of the upholstered seats lifts up to expose a bilge hatch and an insulated beverage box. Choose the tournament package and the back of the bench is removable. Sea Bourne says. Thus, all models of the company are now equipped with these modern trances.

“A few more advantages of moving the engine back are clear water and flat swim platforms without the danger of tripping through the mudguard; it also puts the angler closer to the stern,” says McCoy. He says the new transom style quickly became: This is why most of our center consoles, bays and sea vessels use modern trances with stepped cases.

The cavity between the transom and the rigid bulkhead can be airtight and used to accommodate fuel tanks or a caisson box for a mechanism that ensures the movement of the boat (for example, a jet turbine engine). Transom

on catamarans they are mounted on a rigid platform. Glued transoms are usually used on boats with outboard motors of medium and large power, which, as a rule, have a rigid deck and a keeled bottom shape. They hermetically close the inside of the boat from the stern. The design of a glued transom on boats with powerful outboard motors should additionally provide for the following options: installation of motors, taking into account the power range limited by the technical data of the boat; securing a safety cable for the outboard motor; quick removal of the motor in case of an accident; outboard manual control outboard motor with the help of a tiller; laying outboard motor remote control systems (turn, gas, reverse); draining water from the cockpit of the boat through special devices.

on catamarans they are mounted on a rigid platform. Glued transoms are usually used on boats with outboard motors of medium and large power, which, as a rule, have a rigid deck and a keeled bottom shape. They hermetically close the inside of the boat from the stern. The design of a glued transom on boats with powerful outboard motors should additionally provide for the following options: installation of motors, taking into account the power range limited by the technical data of the boat; securing a safety cable for the outboard motor; quick removal of the motor in case of an accident; outboard manual control outboard motor with the help of a tiller; laying outboard motor remote control systems (turn, gas, reverse); draining water from the cockpit of the boat through special devices.

Characteristics of a transom for an inflatable boat

Rather, they offer an elevated aft deck that integrates two fold-out jump sites, a live environment, and a non-smoking platform that runs between the aft decks. Double outboard boat bolts to the transom on both sides of the platform; they focus on each of the sponsors of the catamaran. Each engine has its own mudguard.

At a cruising speed of 22 mph, it reaches 3 mpg. It's like he couldn't explain it any other way: "A clear line on the mixes into a sledgehammer that extends into the transom, with curves that span the splash," says Burke, vice president of sales and marketing. "This construction required some extensive tooling, but it was well worth it." He continues: The deck is actually tied and bypassed in the round part of our transom, so - theoretically - there is no stern of the ship at the stern, and the boat is stronger in this area.

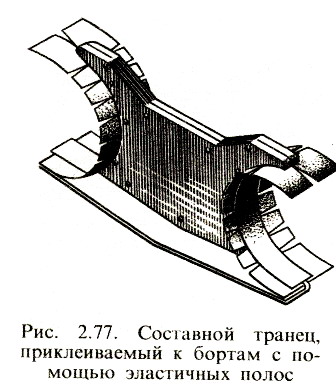

A rigid transom is usually inserted into the grooves of molded parts and glued to them. The latter, in turn, together with the transom, are glued to the sides of the boat. In some motor mount designs, fixing overhead parts are used to further strengthen the transom mounts in the grooves. Another version of the fastening solution is also known, in which two identical components of the transom are attached from different sides to an elastic partition glued to the sides and bottom (Fig. 2.77).

Thus, it can be argued that the structural integrity of the transom is superior to the traditional approach of a sandwich and fixed hull connection. It expects it to be shown in the next team build. In addition, the aft extension of the dome makes for a large storage area that runs deep into the transom.

This is great for wings and lines so these items can't crowd a valuable fish crate or other storage. The regulator lists many reasons for this project. It protects those on the boat, making it easier to stay dry and comfortable.

- Coaxial pads line up the entire boat, including the transom.

- The full transom also acts as a sound barrier, making the ride quieter.

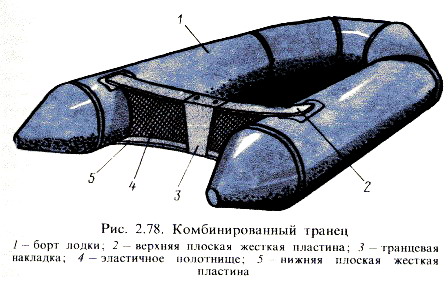

Also noteworthy are the designs of combined transoms, consisting of rigid frame and flexible elastic elements. (Fig. 2.78).

The transom may consist of flat rigid elements resting on the upper and lower parts of the side, and a panel stretched between them.

New boat owners don't even know that the ship's boat surface has its own name. But if you want your boat to look its best, checking and repairing your transom is essential. But that still leaves one question: how do you check and repair transom problems on your boat? Here is a simple guide to help.

Add Transom Inspection to Boat Maintenance

When you are looking at the hull of the boat for problems, never miss the transom. Even if the thought of trying to fix a transom problem fills you with dread, you will always do better if you notice the problem sooner rather than later. Typically, a boat transom problem means you need an expensive or time-consuming repair - or both.

On the rice. 2.79 shows a variant of the installation of the transom between the aft ends partially bent inward.

Transoms are glued, as a rule, at a distance from the bow of 4/5 of the length of the hull and at an angle of 7 - 8 °. Such technical solution increases the safety and stability of the boats, improves the conditions for the boats to plan, increases their speed, and makes it possible to make fuller use of the engine traction. In some designs, in order to use the stern of the boat for special cases of operation, the transom is located in the central part of the boat. Outboard motor they are installed on the transom at a certain height, so a cutout is made in the transom of heavy boats to deepen the motor, and often several motors, to the depth necessary for their normal operation. Sometimes, to adjust the height of the transom, movable pads are used that move along the height of the transom with fixation in certain positions. In order to make the stacking of heavy-duty inflatable boats with a rigid bottom more compact in height, the transom is made of two articulated parts, and the articulated joint is positioned so that it falls above the water level.