How to properly inflate a PVC boat. Pressure in PVC boat cylinders: norm and deviations

For the correct and durable use of a PVC boat or inflatable catamaran, it is necessary to inflate the vessel to operating pressure and not allow it to be exceeded or decreased. If you don't comply operating pressure, then the PVC boat is subjected to unnecessary stress and wears out quickly.

Working pressure in PVC boat

In short, the working pressure in the cylinders should be 250-300 mbar. It is not necessary to use a pressure gauge when inflating; approximately the working pressure can be determined “by eye”. The balloon should bend no more than 1-1.5 cm when pressed with a finger and “ring” a little when slapped with a palm or snapped with a finger. This type of inflation of the balloon is called “until the ringing”. The boat at operating pressure has maximum strength and rigidity, and is completely safe for use.

Boat strength at operating pressure

Dynamics of air pressure in a PVC boat

The volume of air, and therefore the pressure in the cylinder, is highly dependent on temperature changes. The change in gas pressure in a closed space is described by Charles's law.

The mathematical expression of the law is extremely simple:

P1/T1 = P2/T2

T1 and T2 – temperatures in degrees Kelvin (K);

P1 and P2 – absolute pressure gas in a closed volume at temperatures T1 and T2, respectively.

Temperature in Kelvin is obtained by adding the value 273 to the temperature in degrees Celsius. Thus, for example, a temperature of 27 ° C will correspond to a temperature in Kelvin of 273 + 27 = 300 K.

The absolute pressure value is found as the sum of atmospheric and excess pressure in the cylinder. That is, for example, a cylinder has an overpressure value of 250 mbar. If the atmospheric pressure is taken to be 1 Bar, then the absolute pressure will be 1.250 Bar.

Let's start with the calculations. Let's assume that in the initial state the boat has an excess pressure in the cylinders of 250 mBar. The air temperature in the cylinders is 27°C.

When cooling by 10°C, we obtain the absolute pressure in the cylinders:

1.25×290/300 = 1.208 Bar

Thus, the excess pressure will be 208 mbar.

When the air in the cylinder is heated by 10°C, we obtain:

1.25×310/300 = 1.292 Bar, i.e. the excess pressure will be 292 mbar.

The change in temperature can be quite large, 30-40 degrees or more, for example, if you inflated the boat for morning fishing at 10 degrees, and in the afternoon the temperature rose to 30. You must also remember about the ability of the PVC fabric itself from which the boat is made to heat up. In the sun, PVC fabric can heat up 20-30 degrees above the ambient air temperature.

Based on the above, the pressure dynamics in the cylinder can be up to 150-200 mbar.

Damage from low pressure in a boat

It may not be strange, but low pressure in boat cylinders is just as dangerous as high pressure. This is why you should not under-inflate the boat for fear of overheating. There are two main problems low pressure air in boat cylinders:

- Underinflated PVC boatdoes not have the necessary rigidity, which means it becomes an unsafe vessel because stability is greatly reduced. Tensile loads on the fabric increase, which can lead to damage.

- Under-pumped PVC boat MUCH easier to pierce.Even an ordinary branch can damage the boat's cylinders, while at operating pressure the branch will simply slip or break.

A semi-inflated PVC boat is vulnerable to damage

Due to the vulnerability of a “soft” boat to physical damage, when assembling the boat, it is necessary to clear the site of debris, since even simply stepping on the side of an underinflated PVC boat on the shore can damage it.

Harm from high pressure and temperature

You've probably heard more than once that inflatable boats explode in the sun. Let's figure out what's really going on.

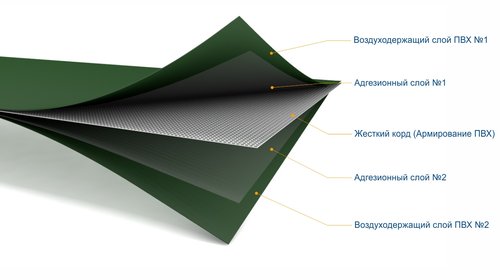

Modern high-quality PVC fabrics, for example, HeyTex or TRW, are very durable and resistant to ultraviolet radiation from the sun, gasoline and oil; in addition to the air-holding layer, they have a special mesh of threads (rigid cord - PVC reinforcement). Therefore, the weak point of a PVC boat is seams and patches when using glue with a low reactivation temperature.

Reactivation temperature- this is the temperature at which the glue becomes liquid again and the seam spreads under air pressure. The glue does not immediately become liquid, but gradually loses its strength over 5-10 degrees, so exceeding the operating pressure in the cylinder accelerates the unraveling of the seam.

In the production of high-quality PVC boats, industrial two-component glue and additives are used that eliminate the possibility of glue reactivation one day after drying. This technology is called cold welding - at the seam the fabric becomes even stronger due to 2 layers.

In our production of catamarans we use only industrial two-component glue.

For low-quality PVC boats, the glue reactivation temperature can be about 50 degrees, which means that in the sun the fabric (especially dark) can easily heat up to this temperature and the seam will unravel.

It's worth remembering not only seams, but also patches if you've ever repaired a boat. Ordinary household polyurethane adhesives do not have a high reactivation temperature, so it is necessary to cover the patches from direct sunlight, and it is better to give the inflatable boat to professionals for repair.

PVC boat bleed valves

There is an opinion that bleed valves are a panacea for exploding boats, but this is not the case. Of course, when the boat is lying on the beach in the sun, the bleed valves will protect the cylinders. However, on water in a wave, an inflatable boat experiences shock loads and the pressure in the cylinders sometimes increases up to 1.5-2 times for a short period of time, while the release valve also releases some of the air in the cylinder. It turns out that the boat is simply slowly deflating while moving, which is just as bad as increased pressure in the cylinders.

Purchasing an inflatable boat requires purchasing a high-performance pump. This is due to the fact that it takes a lot of time to inflate it with the “frog” pump that is included with the boat. As a rule, preference is given to an electric pump that operates from battery car. Despite this, not every PVC boat owner is ready to buy an expensive item.

The choice of pump depends on various factors that can influence the selection process. First you need to decide on the purpose of the pump and its price. Before purchasing, it would be a good idea to pay attention to the following characteristics of the model:

- Acceptability of operation from a battery or car cigarette lighter. Typically, centrifugal pumps operate from on-board network car 12V. Designs with higher performance are connected to both the battery and the cigarette lighter. At the same time, there are models that operate from a 220V network.

- Boats with a length of up to 4 m require an electric pump with a capacity of 300-400 liters per minute. Boats with a length of more than 4 meters require a pump with a capacity of up to 1000 liters per minute. The pump should provide a force of 300-400 mBar, so that you do not have to pump up the watercraft with a manual pump, such as a “frog”.

- The presence of a check valve for pumping air out of the cylinders. This function makes it possible to perfectly pump out air from the boat, which makes it possible to fold the boat more tightly for transportation.

- The presence of a built-in pressure sensor, which allows the pump to operate in autonomous mode. At the same time, there is no need to control air pressure.

- Availability of built-in battery.

5 best electric pumps for pvc boats

It features a built-in power regulator, which expands its functionality. Using a pump, it is possible to inflate not only boats, but also other structures. In eight minutes he can pump up a four-meter boat to optimal pressure.

The user can independently select the operating pressure. After inflating the structure, the device itself is able to turn off, which will protect, for example, a boat from excess pressure. With its help, it is possible not only to pump up, but also to deflate air. The pump comes with connectors for various valve designs, allowing you to pump a variety of valve designs.

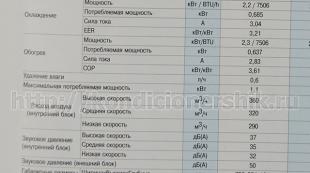

Device specifications:

- Supply voltage – 12 V.

- Current consumption - up to 9 A.

- Capacity – 150 l/min.

- Working pressure - 300 mbar.

- The weight of the structure is 1100g.

It is designed to obtain optimal pressure in air cylinders.

The package includes:

- Hose for connecting to the pump.

- Electrical cable with alligator clips.

- Set of adapters for various valve designs.

- The fitting that connects the air hose to the compressor.

- Built-in pressure control regulator.

- A bag for transportation with the required number of compartments.

To pump up the structure you need:

- Connect the air hose to the compressor and the object being inflated.

- Connect the electric pump to the battery using alligator clips, observing the polarity.

- Turn on the device by pressing the “ON” button.

- Set the required pressure on the sensor.

- After completing all preparatory operations, press the “START” button.

To pump air out of the boat, you should switch the air supply hose to another pipe labeled “IN”. All subsequent steps are the same as when inflating the boat. The body of the device is not protected from moisture, therefore, when near a body of water, you need to be careful not to let moisture get on the device.

Technical characteristics of the electric pump:

- The maximum created pressure is 250 mbar.

- Capacity – 1000 l.

- Current consumption – 45-60 A.

- Supply voltage – 12 V.

- Weight – 3.5 kg.

The pump model is designed for pumping large-sized inflatable boats from PVC.

The package includes:

- Air supply tube

- Cable with alligator clips

- Valve adapter kit

- Pressure control indicator built into the housing

- Keys to turn the pump on and off.

- Carrying bag.

The design consists of two separate blocks. The operation of the device begins with the launch of the first module. When the first module reaches maximum operating pressure, the second, more powerful module comes into operation. When the second unit is turned on, the pump becomes noisier.

If the device does not switch, you should pay attention to whether the battery is fully charged and, if necessary, charge it. Although other reasons are possible.

The boat is inflated as a result of the following steps:

- Connect the air connection accordingly.

- Connect the pump to a power source.

- Connect the pipe to the boat using the appropriate adapter.

- The pressure regulator is set to the desired position, after which the “ON” button is pressed.

To pump air out of a boat:

- It is necessary to switch the air hose to the air pumping pipe.

- Pumping is not carried out autonomously, so you will have to control this process.

Main technical characteristics:

- Maximum operating pressure – 800 mbar.

- Supply voltage – 12 V.

- Current consumption – 15-20 A.

- The device weighs 1.9 kg.

This pump is suitable for inflating watercraft with a working pressure of cylinders of no more than 300 mbar. This is always noted in the boat's passport. The electric pump BRAVO BST 12 is designed on the basis of a two-stage compressor, which allows you to inflate other inflatable structures.

The device kit includes:

- An electrical cable up to 3 meters long, which can be connected to both the battery and the cigarette lighter, as well as a set of connectors for various valve designs.

- Built-in pressure regulator.

- Air hose.

Device characteristics:

- Supply voltage – 12 V.

- Current consumption – 15 A.

- Maximum pressure – 300 mbar.

- Capacity – 500 l/min.

- Device weight – 1.5 kg.

Using this model, you can quickly both inflate the boat and pump out air from the cylinders. Capable of operating both from a 220 V network and from the vehicle’s on-board network with a voltage of 12 V.

The kit includes:

- Pump.

- Tube for pumping air with adapters.

- Converter 220/12 V, as well as a connector for connecting to the cigarette lighter.

- Warranty sheet.

Main characteristics of the model:

- Manufacturer – Intex (China).

- Power supply – 220/12 V.

- Capacity – 600 l/min.

- Maximum pressure – 800 mbar.

- Weight – 3.5 kg.

- Dimensions – 260/160/110.

In order for the pump to please its owner with reliable and confident operation, the following recommendations should be followed:

- Turn on the pump only after thoroughly checking all connections for reliability.

- Operate only with a fully charged battery.

- The device must be installed on the same plane as the inflated object.

- Do not leave the device in direct sunlight or in the cold.

- Do not allow water to enter and avoid mechanical damage to the housing.

- Avoid kinking the hose during operation.

- It is not recommended to work without a break for 20 minutes or more.

- Transport only in the case that comes with the device.

Depending on the output pressure, electric pumps are divided into 3 categories:

- Low pressure pumps (40 mbar). Suitable for pumping up small-sized boats. After preliminary pumping, the boat is inflated with a mechanical pump (frog).

- Medium pressure pumps (500 mbar). With their help, you can pump air into boats up to 4 meters long inclusive, without additional pumping.

- High pressure pumps (800 mbar). Used for inflating large inflatable watercraft, as well as for inflating boats with an Air deck bottom.

Why do you need a high pressure pump (up to 800-1000 mbar)?

As mentioned above, such a pump serves to pump more dimensional devices. At the same time, it has an impressive price. It is better to choose a pump depending on the type of boat and its characteristics.

The advantage of pumps is that a medium-sized boat can be pumped up in 10-15 minutes without much effort.

In addition to everything said above:

- The presence of a pressure indicator allows you to keep control over the process of its operation.

- The presence of a reverse function makes it possible not only to quickly and efficiently inflate the device, but also to quickly and efficiently pump out air from it.

- Models with 220/12 V power supply allow you to save the battery and use it when it is not possible to connect to a 220 V network.

Along with the advantages, the disadvantages should also be noted, which include:

- The need for a power source.

- The device is expensive.

For those who have not yet purchased an electric pump, it will be interesting to know:

- It is recommended to purchase such devices only from well-known and trusted manufacturers.

- The pump is selected based on the volume of your watercraft.

All offered for purchase modern boats made of PVC, you can try to divide them into several basic classes - based on the features of their design. More specifically, the individuality of the cylinders and the bottom of the boat. It is this that influences the algorithm for preparing the boat for launching. We will carefully study all stages of preparation for each type of boat individually.

Let's start from the very little ones inflatable boats having oval shaped cylinders. The boat is pre-inflated until its shape appears, when it can still be easily pressed by hand. When our boat has already taken shape, we install decking slats or, if required, a standard inflatable liner. Carefully place the jars in their places. If necessary and if included in the delivery set, it can be installed mounted transom. At the last stage, after installing all of the above, we bring the pressure in the cylinders to the standard one recommended by the manufacturer.

When inflating the watercraft, we first of all carefully monitor the safety and correct operation of the cups - those membranes that divide the cylinders into compartments. It is clear that when inflating one compartment, not only should it not bleed out, but the second compartment should not inflate either. Thus, when pumping the boat for the first time, we check the integrity of its membranes. In addition to this, in place installing cups a certain tightness may appear (like the body of an ant) - this means that the cylinders are inflated unevenly or too much, it is necessary to equalize or reduce the pressure.

U air valves There are lids, do not forget to close them immediately after pumping - otherwise dirt will get inside and there will be problems with sealing in the future.

The next stage is into the oarlocks put attached oars. From time to time, their pins may enter the standard holes with great force. A sales assistant in a store should help solve this problem. Both when installing the oars and after removing them, it is worth screwing special cap nuts onto each oarlock pin - they serve two functions: they prevent the oar from getting lost during operation and protect the boat from damage to the hull during transportation in a deflated state.

Boats that have a U-shape for their cylinders are recommended to be inflated a little differently. First, the cylinders are given only a basic shape - we slightly inflate them by analogy with previous boats. In this case, it is much easier to lay the supplied plywood and aluminum floors on the bottom. Install and straighten carefully airdeck or the included low pressure insert. Different sections of the floor can be assembled using different algorithms depending on the design. But for the majority of boats being sold, it is recommended to complete the installation by placing the floorboard fragments closest to the stern and placing its last section directly under the clamps located on the transom. At the last stage, you need to place the last two fragments in a “house”. And press near the top of this “house” to complete the laying of the floors. Why press at the top? Otherwise, you can easily get your hand pinched between the aluminum fragments of reinforcement of different sections of the floorboard.

Further, many manufacturers advise for simplification stringer installation put under the bottom of the oar. For those who want to further simplify the process of assembling the boat, we recommend pumping up the keelson a little. Using this elementary trick, you can slightly raise the previously aligned floor right in the center, thus freeing access to its edges when the cylinders are not fully inflated. This method will greatly facilitate the installation of stringers. After making sure that the deck and airdeck, as well as the cans, are in their places, we finish pumping the boat to the standard pressure values. It is better to do this smoothly and slowly. First, we inflate the end sections of the boat cylinders, a little less than the manufacturer recommends. This is all in order to minimize the stresses that can lead to deformation of the boat. And then, we inflate the bows and keelson. When installing payola books, we note that it is a little easier to install it - you can unfold it at the bottom and simply tuck it under the sides. The algorithm for inflating the balloon in stages is the same as for other soldered structures. Various models boats from the same manufacturer and even different elements of the boat may require different pressures, but as a rule this difference does not exceed three tenths of an atmosphere. Close it before pumping starts. air valves. This can be achieved by lightly pressing the spring-loaded valve stem, turning it to the position in which it protrudes into its seat to the greatest height.

Further, many manufacturers advise for simplification stringer installation put under the bottom of the oar. For those who want to further simplify the process of assembling the boat, we recommend pumping up the keelson a little. Using this elementary trick, you can slightly raise the previously aligned floor right in the center, thus freeing access to its edges when the cylinders are not fully inflated. This method will greatly facilitate the installation of stringers. After making sure that the deck and airdeck, as well as the cans, are in their places, we finish pumping the boat to the standard pressure values. It is better to do this smoothly and slowly. First, we inflate the end sections of the boat cylinders, a little less than the manufacturer recommends. This is all in order to minimize the stresses that can lead to deformation of the boat. And then, we inflate the bows and keelson. When installing payola books, we note that it is a little easier to install it - you can unfold it at the bottom and simply tuck it under the sides. The algorithm for inflating the balloon in stages is the same as for other soldered structures. Various models boats from the same manufacturer and even different elements of the boat may require different pressures, but as a rule this difference does not exceed three tenths of an atmosphere. Close it before pumping starts. air valves. This can be achieved by lightly pressing the spring-loaded valve stem, turning it to the position in which it protrudes into its seat to the greatest height.

After finishing using the boat let's sort it out in reverse order. Here, for soldered structures, it is worth following the correct algorithm of actions. We lower the pressure in all cylinders until they lose their clear shape. In this case, the pressure in the keelson should be reduced only slightly. We get a reduction in the expansion effect, thanks to which the shape of the bottom of the boat is formed and the stringer can then be easily dismantled. Next, without much effort, remove the payol.

What you definitely shouldn’t do when inflating a PVC boat.

These prohibitions apply to all domestic boats.

· It is dangerous to use various compressed air cylinders to inflate boat cylinders, only specially designed manual and electric pumps.

· Excess of pressure in cylinders during operation is allowed within ten percent.

· Operation of the boat is not allowed without the valves being closed from dirt.

· Leaving the boat fully inflated in direct sunlight, reduce the pressure in the cylinders by about a third if similar situation can't be avoided.

· Operating a boat with a pressure in the cylinders significantly lower than the standard one can lead to internal damage to the frame of the boat material; if the pressure was reduced for storage, it should be restored before re-use.

· It is wrong to leave the threaded end of the oarlock rod without a screwed-on cap nut - we may either be left without an oar, and therefore without a means of transportation, or tear the boat's cylinder during transportation.

The pressure in the cylinders and other inflatable parts of PVC boats is necessary to give the hull the necessary rigidity and good fixation of the collapsible cockpit deck between the bottom and the inflatable side.

A certain rigidity is also necessary for the correct functioning of additional elements attached to the sides. First of all, these are oarlocks. A control console, chair, tables, ladders, etc. can also be attached to the sides.

As a rule, the operating pressure of boats whose side cylinders include toroidal contours (for example, the transition of the side cylinder into the bow or stern cylinder) is 250 mBar (for reference: the classic toroid is shaped like a “donut”).

The pressure in inflatable elements that do not have toroidal contours, for example, the below-deck keelson of a boat with a collapsible deck or the skegs of an inflatable catamaran, allows higher values, up to 400 mBar. The pressure is built up to this value in the onboard cylinders of sports catamarans of the “Fast Cat” type, which also do not have closing inflatable elements in the bow or stern of the vessel.

This difference in operating pressure values is explained by the following considerations.

Firstly, for the onboard cylinders of “classic” PVC boats, the pressure in the cylinders of 250 mbar is sufficient for the vessel to meet its declared operational capabilities. There is no point in overloading the fabric and adhesive elements of the case, increasing the risk of destruction.

Secondly, the tissue tension on the inside of toroidal cylinders is higher than in a straight cylinder. As a result, stress concentrators appear at the joints at the junction, for example, of side and bow cylinders, the strength of which is sensitive not only to pressure, but also to the quality of execution and design of the vessel.

Thirdly, pumping air through muscular force using a five-liter foot pump to higher values is very problematic, and with a high-pressure pump having a small volume takes an unacceptably long time.

The pressure in the below-deck keelson, which has a small volume and small radius, can be pumped up to 300 - 400 mBar using high-pressure pumps.

It is known that the stress of a cylindrical shell is proportional to the radius.

Since the radius of the inflatable keelson cylinder in the widest part is at least half the radius of the onboard cylinder, then at equal pressure the keelson fabric will experience half the tension, and, accordingly, the element will have less rigidity.

Therefore, if there are no special restrictions from the manufacturer, an appropriate pump is available and the physical conditions of the shipowner allow, the pressure in the keelson should be pumped up to a value of 350 mBar at a minimum.

This will ensure good tension on the bottom fabric, and the boat will have less hydraulic resistance when moving at planing speeds.

In rare moments of movement at maximum speed in rough water conditions, the pressure must correspond to the rated value. Otherwise, from the impact of waves on the bottom of the deck, the boats will “walk”, making frightening sounds, and the bow decks will most likely become a “house”.

Side rigidity is also required during vigorous oaring. Otherwise, the emphasis on the oars will force the oarlocks to press into the cylinder, unfavorably changing the angle of the blade to the water horizon.

In the remaining 99% of cases, for the “classic”, a pressure in the sides of 200 mBar is sufficient. This will significantly save energy when pumping.

PVC boats of the inflatable catamaran class reveal their speed qualities only if they have the required hull rigidity. Therefore, cylindrical inflatable elements that do not have toroidal fragments are inflated to a pressure of 400 mbar. These are skegs of any catamarans and onboard cylinders of sports catamarans “Fast Cat”.

It should be remembered that when the ambient temperature changes, the pressure in the cylinders can change significantly.

Thus, a change in the air temperature inside the cylinders by 10°C in any direction changes the pressure by 42 mBar.

Those. a boat inflated on the shore, after launching, depending on the temperature of the latter, will partially lose pressure.

The operating pressure in the inflatable elements of boats must be indicated by the manufacturer in the operating manual. It is advisable to use a monometer for control. This is a very useful and inexpensive device. The issue price is about 200 rubles.

As shipowners gain experience using PVC boats, they can then quite accurately determine the pressure by the force on the pump, as well as by external signs. Cylinders under operating pressure produce a high-pitched ringing sound when they click. Due to the slight elastic deformation of the PVC fabric, the radius of the balloon between the transverse seams becomes slightly larger, and it seems as if the boat is bursting.

Such a moment as the pressure in a boat made of polyvinyl chloride is very significant and important; the amount of pressure depends on the boat itself and should be 10 kPa or more, which is determined by a number of factors. The pressure depends on many factors, such as the degree of loading, functional significance, dimensions, use and the quality of the device itself.

general information

main feature the pressure of the cylinders is to give rigidity to the body of the device and form fixations of the cockpit between the side and the bottom itself. It is required for the quality operation of the boat itself and for fastening a number of parts from the control console and ladders to seats and others.

To create the operating total pressure, on-board cylinders with toroidal contours are used, where the pressure itself is usually 250 mBar on average. If we are talking about pressure in elements without a toroidal contour, then there may already be a large value, that is, up to 400 mBar or more. In order for the vessel to meet its declared operational functions for a long time, it is important to take into account the loading of adhesive and fabric elements in order to avoid destruction. A boat can even explode in the sun, and this has happened for sure more than once, so today the fabrics used here are of the highest quality and resistant to UV, as well as oils and gasoline.

HeyTex and TRW fabric It is made only from special materials, where the strongest thread is used, so the only weak point here will be the seam. The cylinder, when it is inflated, should bend from finger pressure only 1.5 cm and no more. The main feature of the pressure is that it matches its working qualities, otherwise the boat will wear out too quickly.

How to determine the working pressure in cylinders?

In order for the boat to serve for a long time and efficiently, it is necessary to pump the vessel strictly to the required working pressure, so that there is no decrease or increase there. If it is not taken into account, the boat will be subjected to heavy loads and will wear out faster.

Measuring pressure with a pressure gauge

To determine the total pressure, a pressure gauge is usually used, which shows the operating value 250-300 mbar on average, if there is no such device, then you can check the pumping for deflection with your finger.

Another way to determine it is by sound; a light slap of the palm is enough, which should cause a slight ringing. If this ringing and pressure corresponds, then the boat has already been given the required rigidity and strength, and is ready for use.

Unique qualities of boats:

- Ergonomics.

- Low weight.

- Ease of transportation.

- Long service life.

- Hydrodynamicity.

- Safety.

- Functionality.

The operating pressure is indicated by the manufacturer and it must clearly correspond; here it is better to use a regular pressure gauge, it is easy to use and is cheap.

When you pump up your watercraft, keep in mind that a number of electric pumps, and even ordinary ones mechanical devices will not be able to inflate the boat to the required degree. Here it is better to pay a little more and buy a good pump; it will be the one that will be able to pump the boat up to the strict operating pressure. Such working electric pumps also have a built-in pressure gauge, which is very convenient, whereas mechanical pumps do not have this device.

Mathematical calculation of working pressure

The pressure in the working cylinder depends on the temperature itself; every owner of a PVC boat knows for sure that reducing this temperature will reduce it in the cylinder itself. If the boat heats up in the sun, then the pressure will increase, which leads to the threat of rupture of the cylinder itself, so it is advisable to have it installed.

Here it is the temperature in the cylinder, and not the medium, that should be taken into account; knowing the rate of pressure change, it is possible to determine the stretching of the tissue, which must meet the permissible strict values.

The dependence of the total temperature on pressure will be determined by Charles's law, which is also Gay-Lussac's second law.

Calculation. Let's say the total temperature in the cylinder is 27°C, and the excess pressure in the boat is 250 mBar, the pressure when cooled by 10°C will be equal to 1.25x290/300, which equals 1.208 Bar. Further, it is already possible to obtain the excess total pressure itself, which will be 208 mbar, if the air is heated in the cylinder by 10°C, then the following calculation is obtained, 1.25x310/300, which is equal to 292 mbar this will be excess pressure.

How to pump a swimming device?

Modern wonderful PVC boats are created according to the best technical developments and can inflate as easily and quickly as possible. For this purpose, a special pump is used, which is included in the general kit; the amount of effort and time required to inflate the boat itself depends on the type of such device. Such general functional inflation of a watercraft can be done as quickly as possible, especially if these are modern, good devices.

What the device could be:

Why is low pressure in cylinders dangerous?

If it is low, this leads to heaving of the floors and the formation of an air bubble at the transom, then the propellers may catch and this will increase the trim to the stern, that is, the bow will lift up.

Be sure to use good modern pressure gauges and ensure that the cylinders are properly inflated, which can be checked for sound by hitting them with the palm of your hand and there should be a slight ringing sound.

Every day the product deflates and after 2 days it will drop quite significantly, and this can become dangerous, since under-inflating leads to problems. It must be taken into account that in cold weather, when launching, it will drop, and if the boat is under-inflated, it will fall even more, and this is life-threatening.

If the cylinders are not fully inflated, there is a fear of overheating, and the stability of the entire vessel is greatly reduced and the tensile loads of the fabric will increase and it will be easily damaged. A soft boat is very vulnerable; even stepping on board with under-inflated cylinders can even damage the boat.

Why is high pressure in cylinders dangerous?

If the boat is overinflated, the pressure in its cylinders will quickly increase due to the hot sun and the boat can literally explode and sink. The geometry of the structure changes very much and air cylinders can easily and quickly be punctured even by a small ordinary twig, so pumping is very dangerous for human life.

The seams on the boat must be smooth and well taped so that they do not come apart if accidentally pumped.

To avoid this terrible phenomenon, you just need to pump strictly to the required value, which is recommended by the manufacturer, and this is controlled by a regular pressure gauge. The pressure gauge must be of good quality, and if the boat’s passport indicates 0.25 atm, then pump the boat to 0.24-0.26 atm, which is of great importance.

Modern PVC boats are durable and resistant to ultraviolet radiation, as well as to the effects of oils and gasoline, since, in addition to the air layer, there is a special mesh.

Because of the sun, the fabric, especially if it is dark, easily heats up and the pressure in the cylinder will increase even more, and if it is inflated too much, then there will definitely be damage and the seams will unravel because of this.If patches have been made, then only heat-resistant glue should be used, and the glue layer itself should be protected from sunlight; such repairs should only be carried out by experienced workers. The pressure in the cylinders can increase even due to the shock action of the wave, and if the pressure is more than required, then it is already life-threatening.

What is unsafe at work?

Required good quality seams and cylinders, you should rationally select the dimensions and check the quality of the bottom, which can be hard or balloon.

A balloon bottom, that is, an inflatable one, reduces the weight of the boat and its cost, although the stability will be weak, which is only suitable for a quiet body of water and this should be taken into account.

Danger at work:

Danger at work:

- Hitting the boat with a branch or stone.

- Severe overheating.

- Storm.

- Big wave and strong wind at sea.

- If the pressure in the cylinder is less or more than required.

Manufacturing materials must be wear-resistant and durable, the best option This is polyvinyl chloride, which is much more effective than rubber, since it is lightweight and vulcanizes well, although it is afraid of aggressive action from the outside. A very important element here is the seam, and more attention should be paid to it; it should be neat and even so that it does not come apart in the heat.

It is advisable to take into account the color of the structure, since a dark boat can become very hot due to the sun and will definitely explode when pumping the cylinder.

The shape is also a significant indicator of operational safety; a wide side has great wind resistance, while a narrow side allows water to enter the boat.

Piercing fabric

Such a wonderful and durable material like PVC is very functional and quite durable, especially if it was reinforced with polymer threads, which are very rigid and stable. Thanks to the reinforcement, this material becomes resistant to tearing and cutting, although due to too much pressure in the cylinder it can easily be pierced and destroyed under the influence of UV and shock wave forces.

Another weakness- these are seams and if they are made with poor glue or the welding is carried out incorrectly, then a puncture is possible in this place, this also applies to patches.

It is believed that the denser the fabric, the stronger it is, and in order to reduce the ability to damage the fabric, it is better to buy European boats rather than Asian ones, as they last longer.

Sinking

To reduce the possibility and probability of sinking, it is advisable to use a removable bottom of low or high pressure, since this makes the bottom more resistant and also ensures relevance. That is, a strong common deck is formed, which is not pressed by a person and the boat becomes more stable.

If previously they used slats made of plywood or metal, now they have begun to use removable high-pressure products that are more durable and easier to assemble, and they also serve as thermal insulation. Modern watercraft can have great characteristics carrying capacity, so their sweating capacity has become less.

The need for bleed valves

If there is a shock or normal overheating, the air is immediately released automatically from a special valve to the required value.

Today, most watercraft are assembled using special bleed valves, which will be very useful here. important element. Such a valve is required to release excess air, so it will no longer be possible to pump, and this is an important point.

A special operating valve for bleeding is very practical and important with a critical, rapid increase in pressure by large values, and this can happen with strong heating on a salt lick and during a wave shock, the cylinder will not rupture.

Due to the high temperature and significant pressure, the cylinders in the boat will work at maximum speed, and to avoid further damage, a bleeding valve must be installed.

- Before inflating with air, it should be unpacked and kept 60 minutes at an average temperature of 20-30°C; for inflation, use an electric pump rather than a tire compressor.

- A flat, cleared area is used to assemble the floating device., the cylinders are pumped clearly one by one according to the instructions. Be sure to use safety points, the operating mode should be from -5 to +45°C, and if the temperature is not taken into account, the likelihood of damage will be high. It is required to do regular general monitoring of the pressure in the cylinders, since a decrease and increase leads to damage to the boat.

- It is not recommended to operate a watercraft while intoxicated, and if there is no special lighting device there, then use it only during the day. If a motor is used, it should not be very powerful, otherwise there will be problems with control; another important factor is the installation height of the motor.

- Please note that excessive loads it is dangerous here, this occurs during strong waves and fast movement. It is prohibited to suddenly accelerate; if there are no passengers, then it is better to position yourself closer to the front; if there is cargo, then it is better to think about its precise location, otherwise damage to the boat is possible.

- The product can be stored at temperatures up to +50 C and humidity up to 80%, try to avoid damage to the fabric during storage.