Water jet boat with car engine "Pilad. Jet boat "Moray"

As a rule, people who decide to connect their occupation (be it a hobby or profession) with bodies of water such as rivers or lakes, sooner or later face the problem of choosing a boat and the type of propulsion for it. Motor-water jet or propeller? Each has its own pros and cons. How to choose what to pay attention to? And is it even worth making a choice between a water cannon and a classic motor with an open propeller?

Water jet propulsion

A water jet is an engine that propels a vessel using the force created by a water jet.

The propulsion unit consists of a propeller with a shaft (impeller), a jet tube, a straightening apparatus and a steering device.

The principle of operation is that water flows through an impeller into the water intake compartment, and then the liquid is discharged through a cone-shaped tube, the outlet of which is smaller in diameter than the inlet. This creates a jet that ensures the movement of the motor boat. With the help of a steering device, the direction of movement of the jet is changed by turning the propulsion in a horizontal plane, which ensures turns of the vessel, and blocking the outlet creates a reverse flow, providing the boat with reverse motion.

People who often have to overcome littered or rapid bodies of water are usually inclined to choose water cannons. A conventional propeller motor in these conditions risks becoming unusable due to the high risk of mud wrapping around the propeller in shallow water or the usual entry of large debris. IN similar situations Water jet propulsion is indispensable, providing high speed, maneuverability and safety.

You should not limit yourself to the opinions of participants in various forums. After all, not every review allows you to get a complete picture. A water jet is not only a rather complex design, it may not be suitable for every model of vessel. If a beginner is satisfied with the very idea of using a vessel with a water-jet propulsion, he should opt for a ready-made version of the vessel with a water-jet in the factory configuration. Moreover, it is advisable to choose a manufacturer that has been producing these propulsors for quite a long time.

Advantages and disadvantages

The design of the water jet is special in that all the most important moving parts are “hidden” inside the body. If a boat runs aground, the ship's hull touches the bottom. This feature design allows you to protect parts from damage, which cannot be said about outboard motors with a “bare” propeller. The water jet propulsion system is not afraid of encounters with underwater debris.

When a motor boat moves in shallow water with a depth approximately equal to the landing of the hull (about 20 centimeters), the water cannon allows you to overcome littered areas, as well as places with obstacles protruding from the water, thanks to its maneuverability.

If you hit an obstacle at a depth of about 30 centimeters, the impact will be taken by the bottom of the boat, not the water jet, since the propulsion unit has no protruding parts, which is not the case with an outboard engine, where the impact is taken by the blades

Sometimes water jet propulsors are also used on pleasure boats due to the soft operation of the power train (transmission) and the absence of vibration.

The advantages also include the absence of additional resistance to water, which is typical for engines with an open propeller (the propeller blades create additional resistance). In addition, they have high inertia values and more comfortable handling at high speeds (both in forward and reverse). The low noise range is also of considerable importance: an outboard water jet is noticeably quieter than a motor with a propeller.

However, it should be noted negative side: when moving in shallow water, there is a high risk that stones, sand and debris from the bottom will be drawn into the engine, because the water cannon works on the principle of a pump pump. This can lead to damage to the impeller, failure of the cooling system and incorrect operation of the drain nozzle.

Another negative side is friction. This is due to the high speed of water movement inside the pipe. Don't forget about the cost of installation. about twice the price of regular ones outboard motors with open screw. Because of this, boats with a water-jet propulsion system add significantly to their cost and are perceived by clients as a whim or an unaffordable luxury.

The water jet control system is also unusual for fans of classic screw motors. The problem stems from the fact that the classic open propeller propulsion system has a single-lever control system. Water-jet propulsors have a multi-lever reversible steering device. Some manufacturers manage to produce boats with a built-in water jet with a single-lever control system. On the one hand, this helps to master the water cannon, on the other hand, it is more likely to entail troubles than bring benefits:

- Firstly, a beginner has the wrong idea about the operation of a water jet propulsion system. This is due to the lack of a gearbox that allows you to move the gearshift lever to the neutral position. The gearbox can either engage or disengage the clutch. The water-jet propulsion system picks up speed smoothly when turned on; you should not expect an instant reaction in the form of a jerk from a standstill.

- Secondly, for a better understanding of the principles of operation of a water cannon, it is recommended to take an appropriate training course. The whole trick to controlling a water jet propulsion system is the need to use the gas lever (to increase the speed of movement) only in open water. When driving along a rapid river, it is better not to do this.

- The third important disadvantage, characteristic of any type water transport- overgrowing. This problem is especially acute with a water cannon, since all the moving parts are located inside. There are no problems with constant use of the propulsion device. However, if the boat is not used for a long time, the insides become overgrown. In particular, fouling of the insides of the drainage system leads to a decrease in movement speed by up to 10%. The problem can be solved by disassembling the water jet and cleaning it manually, but if powerboat has been inactive for a very long time, you will have to contact the workshop and look for suitable spare parts for boat motors. Using a special coloring composition will solve this problem, but not for long: the constant movement of water will quickly wash away this paint.

Jet boats of the Tom series have proven themselves in operation. The boats are designed for fishing, hunting, walking and recreation on the water, water excursions, water tourism, long-distance trips with long-term autonomy, and use as service and traveling craft.

Tom boats are successfully used on lakes, reservoirs and rivers with unequipped banks and shallow waters, on narrow and winding rivers with any kind of soil, with shallow depths and rifts. In difficult weather conditions.

The boat's all-metal aluminum hull is made using riveted-welded technology from an environmentally friendly, corrosion-resistant, easy-to-maintain aluminum-magnesium alloy. Thanks to this choice, the boat hull retains its strength and durability throughout the entire operation of the boat. appearance. The thickness of the boat bottom plating is 4 millimeters. Expanded polystyrene blocks located along the sides of the boat, in case of damage, ensure its complete unsinkability and keep the crew afloat.

The water-jet propulsion system ensures fast speed, confident planing, excellent running and maneuverability, precise handling, and ease and safety of the boat's operation.

This model of water-jet propulsion uses steering with original controls reverse.

This water-jet propulsion system showed its best qualities in shallow and rocky rivers.

To ensure long-term operation of boats with water-jet propulsors of the "Tom" series, in conditions remote from service centers, without the possibility of stationary repair, the design ensures high maintainability of the components and mechanisms of the boat's water jet. The jet propulsion unit is removable and can be easily disconnected from the boat, even while afloat. This allows, if necessary, to carry out unforeseen restoration repairs of the water cannon in the field on your own.

|

We all want to own only the best things, to use them with comfort and pleasure. A clear definition of your goals will help you understand which things or devices are the best for you. Absolutely the same principle applies when choosing a boat.

You can often hear that buying a boat from a famous brand means simply overpaying for a big name. Of course, it is necessary to take into account the budget, but if you think about it, the fame of the manufacturer does not come out of thin air.

Why do you need a jet boat?

A jet boat is a vessel with a water jet engine. It has many advantages both for fishing and for water recreation (water skiing, cheesecakes, bananas, swimming). A boat with such an engine is the safest for people in the water, since the propeller blades are hidden inside the pipe.The pump-type design is less efficient than an outboard with a propeller, but is less susceptible to damage from hitting the bottom or debris.

Weldcraft - boats from a famous manufacturer

The American manufacturer of jet boats with an aluminum alloy hull Weldcraft has been successfully operating since 1968.In the mid-60s of the last century, Norman Evan Riddle decided to create his own boat, using his experience in alloys and knowledge in design. Weldcraft was founded in 1968 in Clarkston, Washington, near the Snake River. The idea quickly turned into a lifelong endeavor with a rich legacy.

Modern boats with jet engines from the manufacturer Weldcraft present not only new developments, but also improved versions of the legendary series:

- The Cuddy King, with the ability to install a jet engine, is designed to conquer the harsh sea waves;

- Ocean King is a jet boat with an all-welded cold-rolled aluminum hull, a powerful frame with reinforced souls, created with the needs of anglers in mind;

- Legacy - clever layout with cabin and ski tow;

- Select - spacious jet boats with panoramic windows and mosquito nets;

- Saber has a durable aluminum body. Bathing platform frame with reinforced arches. Compact sizes.

- Renegade is the perfect combination of stylish design and maneuverability.

KS water-jet boats have excellent running properties and good maneuverability. The water cannon on them makes it possible to walk in shallow water without slowing down, jumping over shallows, which is very important for the conditions of Russian water bodies. Another advantage of a water cannon is that it reduces the risk of injury to people who swim nearby. In addition, there are no protruding areas under the bottom. The boat can reach high speed in a matter of seconds. It retains its excellent maneuverability even at high speeds.

Boat hulls are made entirely from an alloy of magnesium and aluminum. The boats clearly follow the helmsman's commands, showing perfect handling. They obediently enter turns and clearly return to their original trajectory. The boats also behave decently in rough conditions.

Distinctive characteristics of KS water jet boats:

- High security.

- Excellent handling.

- Heavy-duty aluminum housing.

- High speed characteristics.

- Excellent cross-country ability in clogged waterways and shallow areas.

- Modern design.

The interest shown by amateur shipbuilders in jet boats, is not accidental. In our conditions, such boats have tangible advantages over boats equipped with a propeller drive or motorboats with outboard motors.

First of all, it is high cross-country ability water jet vessels, making many shallow rivers accessible, simplifying the approach to an unequipped bank and parking a boat on the water. The rotor of a water jet propulsion system is better protected from damage when hitting underwater obstacles or floating objects, as a result of which the propellers most often lose their blades. Water jet propulsion, equipped with a hydraulic reversing device, is much easier to manufacture on your own than an angular sterndrive or reverse gearbox. Powerful and economical engines, “heads” of outboard motors, and motorcycle engines can be paired with a water cannon.

However, it is necessary to immediately make a reservation that a water cannon does not have any advantages in speed compared to screw boats. On the contrary, the additional resistance of the water washing the water intake, its rise (even to a small height) for release in the surface part of the boat’s hull cause a slight decrease in the speed of water-jet vessels. This reduction can be very significant if the propulsion unit is manufactured carelessly and is used on ships that are not suitable for this chain. Experience shows that top scores can be obtained by using a water cannon on light planing boats equipped with a fairly powerful engine.

These considerations were taken into account when preparing the next boat project for self-build. The proposed option involves installing on the Murena a 30-horsepower Whirlwind engine with a standard gearbox, but without the stern tube, suspension and hood. It will be necessary to make a lightweight foundation resting on the longitudinal beams of the hull set, install cooling and exhaust systems and, of course, make a water-jet propulsion unit.

Instead of a PM engine, you can install any other engine that is similar in basic characteristics - power, weight, rotation speed and dimensions. The engine from the Moskvich car will be a little big for the proposed one; in this case, it is better to lengthen the body to 4.75 - 5 m.

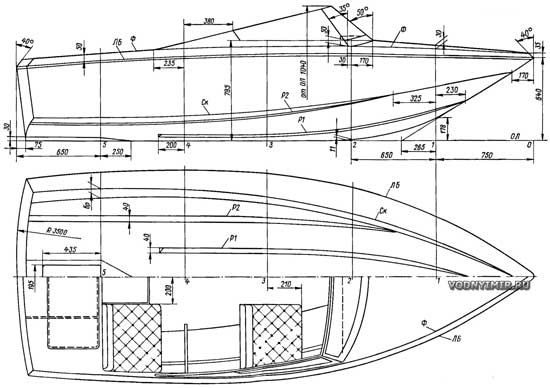

General location of the Murena water jet boat

enlarge, 1500x1057, 146 KB

The wishes of many KiYa readers have been fulfilled: the design of the hull provides for its construction from fiberglass or a composite structure - from plastic on a wooden set. The latter method is convenient for individual construction, since it does not require the production of rather labor-intensive equipment - a punch and dies, which are then discarded.

It is possible to manufacture a body and an entirely wooden structure. In this case, we refer the reader to the third edition of the book “15 ship designs for amateur construction” (“Shipbuilding”, 1985), which describes in sufficient detail the methods of basic work and from which you can select the cross-sections of all the connections of the set, using a project similar in dimensions . To make it easier to cover the sides in the bow that have a concavity, you can use strips of plywood 150 - 200 mm wide, laying them diagonally at an angle of 45° to the fender, always in two layers. Then the skin is covered with two layers of fiberglass with an epoxy binder.

A few words about the contours of the boat. They are typical for modern planing vessels operating on rivers at wave heights of up to 0.75 m. Due to the moderate deadrise of the bottom (17° at the transom), overloads when sailing in rough seas are small. Wide bilge splash guards and longitudinal steps make it possible to slightly increase the hydrodynamic quality and reduce the amount of spray escaping from under the bottom. The high freeboard and large width of the hull along the deck ensure safe navigation on waves of the specified height and convenience for accommodating four people in a relatively small boat.

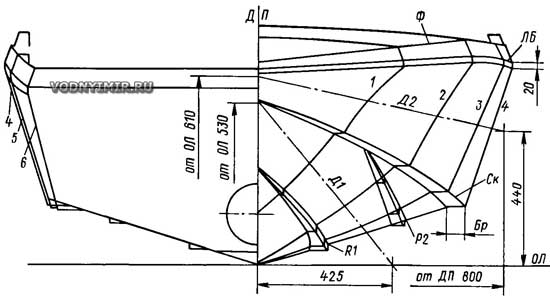

Theoretical drawing of the water jet boat "Moray"

| Table of ordinates of theoretical drawing, mm | ||||||

| Theoretical drawing line | Frame numbers | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Heights from OL, mm | ||||||

| Bulwark - F | 710 | 730 | 730 | 714 | 676 | 635 |

| Side line - LB | 657 | 676 | 673 | 653 | 625 | 585 |

| Cheekbone - SK | 418 | 310 | 235 | 195 | 182 | 182 |

| Half latitudes from DP, mm | ||||||

| Bulwark - F | 445 | 667 | 775 | 802 | 788 | 774 |

| Side line - LB | 465 | 690 | 800 | 829 | 810 | 760 |

| Cheekbone - SK | 276 | 490 | 622 | 680 | 686 | 660 |

| Diagonal - D 2 | 363 | 592 | 725 | 775 | - | - |

| Diagonal - D1 | 260 | 440 | 525 | 557 | - | - |

| Redan - P2 | - | 410 | 462 | 475 | 475 | 475 |

| Redan - P1 | 76 | 190 | 220 | 230 | - | - |

| Width of the mud guard along the cheekbone - Br | 28 | 48 | 57 | 62 | 70 | 75 |

Frames must be made to the full height of the sides along with deck sections or beams. On the plaza you should immediately mark a shergen line, using which temporary strips are attached to the frames. Then the frames and the stem and keel, glued in advance according to a template of two slats, are installed on a slipway consisting of two parallel boards. The hull will be built in a keel up position, just like boats of wooden construction.

Making a convex transom can cause some difficulty. Its shape is determined by two shelves 3 and 29, the trailing edge of which is processed along the radius. A sheet decorator is attached to them - fiberglass or thin plywood, then bars for decorating the edges of the bottom and sides. A convex transom improves the appearance of the boat, but if you sacrifice this, you can make it flat.

When the frames, transom and keel with stem are installed and aligned on the slipway, the fender beams and bilge stringers are cut into the frames. You will notice that their cross-section is significantly smaller than that of boats of wooden construction - just like the frames, the longitudinal slats serve only to design the contours of the hull. The required width of the zygomatic splash guard is obtained by gluing short slats or pieces of foam between the frames to the stringer. At the same stage, foam frames for the longitudinal beams of the engine foundation are inserted on the bottom between the frames, which are subsequently covered with fiberglass. The distance between the beams must be consistent with the sub-frame or engine mounting brackets.

Applying a piece of plywood to the slats of the exposed set, remove the bevel from their edges, then cover the set with fiberglass sheets 1.1 - 2 mm thick. If you can’t get this material, you can make the sheets yourself using fiberglass and binder prepared for molding the body. The process is described by L. Nefedov ().

Sheets of the required sizes are glued onto a table, which must be installed outdoors. Tracing paper or cellophane or polyethylene is spread on the table, serving as a separating layer. 3 - 5 layers of fiberglass are applied to it, onto which an epoxy binder with a plasticizer and hardener introduced into it is evenly applied, and the bag is ironed with a heated iron. Due to the fact that the viscosity of the heated resin decreases, the binder well saturates all layers of fiberglass. In those places where there was not enough binder, you can apply an additional portion of it and iron it again. After 20 - 30 minutes, the process of partial polymerization begins, during which the sheet of plastic acquires a certain rigidity, but it can still be cut with a shoe knife and small shoe nails can be punched through it.

When ironing, the iron must be periodically cleaned of resin adhering to it using a sharp knife, and also ensure that the iron does not linger in one place. The heated area may stick firmly to the iron and the plastic blank will be damaged.

| Optimal binder formulation (component content,% by weight) |

|||||

| 1 | 2 | 3 | |||

| Resin PN-1 or PN-3 | 89 | Resin NPS-609-21M | 85 | Resin ED-5 | 75 |

| Isopropylbenzene hydroperoxide (hyperiz) | 3 | Hyperiz | 4 | Dibutyl phthalate | 15 |

| NK accelerator (cobalt naphthenate) | 8 | NK accelerator | 10 | Polyethylenepolyamine | 10 |

| Co-accelerator T | 1 | ||||

From the place of the body that is supposed to be covered with a sheet of plastic, a template made of cardboard or thick paper is removed, cut along the contour and placed on the blank for marking. The edges of the parts of the set that will be adjacent to the sheet are lubricated with a binder, then the workpiece is put in place and attached to the frames and slats of the longitudinal set with small nails. If a sheet of plastic sags under its own weight, you should continue the process of polymerization of the binder - hang the sheet in the sun or use reflectors for heating. In this case, you need to check that the workpiece does not become so rigid that it is impossible to pierce the plastic with a nail or bend the sheet along the contours of the body. If you use ready-made fiberglass, you will have to drill holes in it for nails.

This way the entire surface of the housing is covered. It is advisable to make joints and grooves of individual sheets at the edges of the set. All irregularities in the sheathing are filled with epoxy putty, joints and grooves are glued with fiberglass tapes in 2 - 3 layers.

After soaking for two to three days, the plastic acquires sufficient hardness to sand its surface and begin gluing the entire body with additional layers of fiberglass to the required thickness (on the bottom 4 - 4.5 mm, on the sides 3 - 3.5 mm). When laying the last layer of fiberglass, you can add a coloring pigment to the binder or paint the boat after construction with pentaphthalic enamels.

Using this technology, it is possible to pre-fabricate a three-layer shp bulkhead. 5 with foam filler between the outer layers of fiberglass, as well as longitudinal partitions in the engine compartment separating fuel tanks And battery from the engine.

The formation of longitudinal edges requires special attention. It is best to paste the body with two or three layers of fiberglass, stick blanks of redans made of hard foam plastic (at least made of wood) on the bottom and cover them in 2 - 3 layers with fiberglass tapes so that the edges of the tapes extend to the bottom by 25 - 40 mm. Lay subsequent layers of fiberglass on the bottom in the form of narrow strips between the edges.

It is recommended to reinforce the keel and stem, the transition points between the transom and the bottom and sides with additional layers of fabric.

After the hull is freed from the slipway, it is turned over and the design of the deck begins. This is done by gluing foam blocks between the frames. After polymerization of the glue, the parts of the foam protruding beyond the edges of the frames are cut off, the foam is processed with a plane or a “grater” (a sheet of tin with holes with burrs punched in it with a nail), then with coarse sandpaper. At the bow and stern, slats are cut into the beams, which will support fiberglass sheets when layers of fiberglass are glued onto them.

Having covered the aft and bow parts of the deck with fiberglass, a hatch cutout is made from wooden slats in the stern. The edges of these slats, lubricated with a separating layer (for example, Vaseline or floor mastic), are folded over the edges of the fiberglass, forming a coaming for the hatch cutout; After the plastic has cured, the slats are removed, and a corresponding cutout is made in the fiberglass. At the bow, foam is glued to the deck to form a lip for attaching the windshield. Then additional layers of fiberglass are molded onto the deck (it is enough to stick 2 - 3 layers onto the foam decorators of its side sections).

A few words about the materials for the manufacture of the “Moray Eel” body. A durable and waterproof body is obtained if you use satin-weave fiberglass of the T11-GVS-9, ASTT (b) C2 brands. With the inherent thickness of these fabrics being 0.25 - 0.3 mm, one layer of fiberglass in the casing gives a thickness of 0.4 - 0.5 mm, so on the bottom you need to lay (taking into account the thickness of the fiberglass decor) 8 - 10 layers of fabric, on sides - 6 - 7 layers. In total, the production of the Murena body requires 130 m of fiberglass, which is produced in a width of 0.9 m.

For the outer layer and molding of various parts, a thinner SE-01 plain weave fiberglass mesh is recommended. It hides the rough texture of fiberglass, smoothes the surface well, tightly fits joints along small radii and holds the decorative layer of resin well.

It is important to maintain the condition that the weight of the binder used to form the layer is equal to the weight of the fiberglass reinforcing it; It is better if deviations in one direction or another do not exceed 5%.

Work on forming the body should be carried out in a well-ventilated room or in the open air. In the latter case, it is important to choose dry and warm weather 17 - 25°C. You need to work with rubber gloves, carefully washing off any drops of binder from your skin. When gluing the body, first apply a layer of binder to its surface with a brush or spatula, then lay glass fabric and carefully smooth it, achieving good impregnation and the disappearance of folds and air bubbles. If the surface is laid with several panels of fabric, their edges should overlap each other by 20 - 40 mm. When covering the deck, the edge of the panel should overlap the upper edge of the outer skin by 25 mm.

Recommendations for making a punch, dies and molding a bulk hull can be found in the article on building the Kalan mini-yacht (). The book by P.P. Katkov and V.V. Kushelev “Technology of Plastic Shipbuilding”, L-d, 1986 “Shipbuilding” is also useful.

D. Kurbatov, “Boats and yachts”, 1989, No. 02 (138).

Drawings of the water-jet propulsion and motor installation of the Murena boat.